- Packing - Handling - Logistics

- Conveying

- Weighing machine

- Christiaens Agro Systems B.V

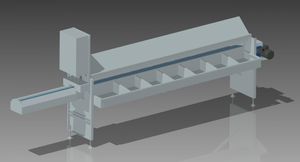

Weighing machine

Add to favorites

Compare this product

Characteristics

- Production speed

21,600 p/h

Description

This line is weighing every single product and makes packages on an adjustable weight. The

maximum capacity of the line is 21.600 pc/hour.

The line exists of a supply conveyor belt and the packaging machine.

Each individual cup is weighed by a load cell. The control system is dividing the product to the exits to make an optimal package with as little variation as possible.

It is possible to adjust the desired weight and margin on the touch screen. The system is dividing the product to the exit to the desired minimum weight. The margin is depending on the product.

If the margin is too small it will take longer before the package is ready. If it’s not possible to divide the products to the outputs it goes to the last exit. It is possible to complete the package after a certain time independently of the overweight. This in order to increase capacity.

The standard machine is equipped with 6 exits on belts and 1 overflow exit. The belts are equipped with a trough system that makes it easier to pick up the package. The exit belt is waiting until the package is complete then moves the package so the next one can be made. On the end of the belt there is a sensor. This is detecting if there is a package on the belt. It is possible to extend this line with binding machines.

Advantages

Labour savings

Minimum giveaway weight

Reliable and maintenance friendly

VIDEO

Catalogs

No catalogs are available for this product.

See all of Christiaens Agro Systems B.V‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.