- Food industry

- Other Food Machinery

- Food grader

- Christiaens Agro Systems B.V

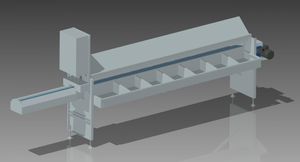

Food grading machine rolleropticalsorting

Add to favorites

Compare this product

Characteristics

- Applications

- for food

- Technology

- roller, optical

- Other characteristics

- sorting, belt, with conveyor

Description

White or green asparagus is laid on the machine where it can cut it to the right length. By the washing part it is cleaned from both sides while the chains are holding the product. Asparagus is falling in the cups on the separation part where it is possible to control the singulation of the product. The vision system is measuring the asparagus on length, diameter, single and double curvature, forms and colours. The patented 3D measurement can measure the closeness of the head. The number of grading options for white and green asparagus are infinite. Customer can define which grading is send to which exit(s). People can take the asparagus out of the exit and put them in the boxes. The line can be adjusted to the customer requirements. From compact to industrial, surrounded by custom made logistic. Almost anything is possible, so the machine matches the way of working.

Advantages

Separation control

Custom made

Uniform grading

Options

Input belt, extension infeed part, extra spacing belt, several water recycling systems possible,

extension separating part, Water cutting system, Barcode scanner, Multiple cameras and 3D

measurement, light for filling rate measurement, weighing systems, making packages and mixing possibilities, integration peeling machine(s), small or big outputs, waste discharge systems, conveyor belts, roller conveyors, box plates, processing tables, custom made logistics.

Catalogs

No catalogs are available for this product.

See all of Christiaens Agro Systems B.V‘s catalogsRelated Searches

- Sorting machine

- Automatic sorting machine

- Food washing tunnel

- Food sorting machine

- Sorting machine for the food industry

- Vegetable food cleaning machine

- Gauging

- Processing plant

- Automatic food washing tunnel

- Food grader

- Mechanical grader

- Process sorting system

- Belt food cleaning machine

- Gauging with conveyor

- Sorting grading machine

- Processing line for the food industry

- Vegetable sorting machine

- Spraying food cleaning machine

- Brush food washing tunnel

- Roller grading machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.