O-ring seal 7550rectangularelastomersilicone

Add to favorites

Compare this product

Characteristics

- Type

- O-ring

- Configuration

- rectangular

- Material

- elastomer, silicone

- Application

- shaft, rotor, handle, key, powder

- Fluid

- air

- Other characteristics

- dynamic, molded

- Temperature limit

400 °F

(204 °C)- Diameter

Min.: 3 mm

(0.118 in)Max.: 8 mm

(0.315 in)- Outer diameter

Min.: 4.7 mm

(0.185 in)Max.: 11.4 mm

(0.449 in)

Description

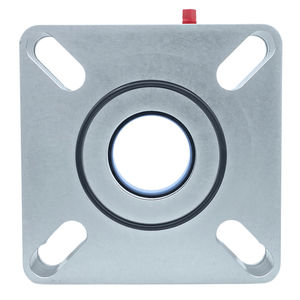

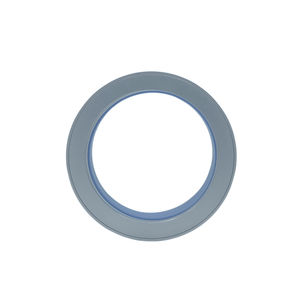

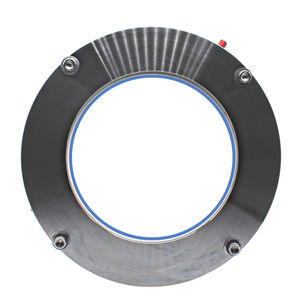

The key component of the 7500 rotary shaft seal design is the solid elastomer, which is made from FDA approved silicone and can handle temperatures up to 400F degrees. The 7550 model is more suitable most powder applications. The elastomer is molded slightly smaller than the shaft size so that an interference fit is achieved. It is this tight fit that seals the shaft, which stops material from migrating past, and drives the two rotating faces called “rotor cups”. The rotating rotor cups compressed against the two stationary stator plates is what creates the primary seal that stops product leakage. These dynamic seals are also air purged at 5 to 7 PSI above any pressure in the vessel to assist in maintaining a positive seal. The key component of the 7500 rotary shaft seal design is the solid elastomer, which is made from FDA approved silicone and can handle temperatures up to 400F degrees. The 7550 model is more suitable most powder applications. The elastomer is molded slightly smaller than the shaft size so that an interference fit is achieved. It is this tight fit that seals the shaft, which stops material from migrating past, and drives the two rotating faces called “rotor cups”. The rotating rotor cups compressed against the two stationary stator plates is what creates the primary seal that stops product leakage. These dynamic seals are also air purged at 5 to 7 PSI above any pressure in the vessel to assist in maintaining a positive seal.

Catalogs

7550

3 Pages

7500 Series

2 Pages

Related Searches

- Polymer seal

- Mechanical seal

- O-ring gasket

- Circular gasket

- Metal seal

- PTFE gasket

- Metal mechanical seal

- Cartridge mechanical seal

- Silicone gasket

- Shafts seal

- Dynamic gasket

- Elastomer gasket

- Stainless steel gasket

- Industrial gasket

- Rectangular gasket

- Housing gasket

- Air gasket

- Shaft mechanical seal

- Mechanical gasket

- Molded gasket

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.