- Production Machines

- Forming Machine

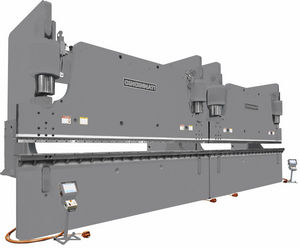

- Hydraulic press brake

- Cincinnati Incorporated

Hydraulic press brake PROFORM + seriesCNC

Add to favorites

Compare this product

Characteristics

- Operation

- hydraulic

- Control

- CNC

- Press force

Max.: 3,433 kN

Min.: 882 kN

- Folding length

Max.: 10 in

Min.: 8 in

Description

The Proform+ has dual pressure transducers on its hydraulic cylinders for increased tonnage accuracy, and digital encoders to deliver ±0.0004 (0.01 mm) ram repeatability for close-tolerance forming and higher part quality. The press brakes PC-based control is now bed-mounted to the machine with a swinging pendent arm mount, and has been upgraded to include a trackball and keyboard. An optional Wila crowning system compensates for bed and ram deflections during bending, and eliminates the costly trial-and-error approach used in traditional die shimming. Available Proform+ models include 90- to 350-ton capacity and overall bed lengths from eight to 16 ft.

The Proform+ includes numerous premium-engineering features that ensure reliable, long-lived operation. Clevis-mounted cylinders and centerline loading confine operating stress to the main housing, eliminating cylinder misalignment. The Machines Variable Volume Load Sensing (VVLS) hydraulic system lowers maintenance costs and increases energy efficiency. Hydraulic cylinders use hardened piston rods with precision guiding to minimize oil leaks, and the machines heavy plate frame is precision machined and rigidly interlocked not welded to better resist deflection for years of precision forming at maximum loading.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Cincinnati Incorporated‘s catalogsRelated Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.