- Industrial machines and equipment

- Furnace and Heat Treatments

- Chamber oven

- CKIC / Changsha Kaiyuan Instruments Co., Ltd

- Products

- Catalogs

- News & Trends

- Exhibitions

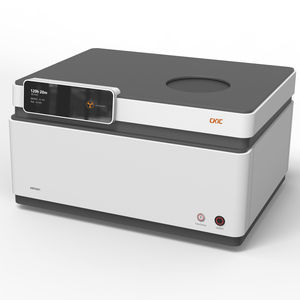

Chamber oven HF3000meltingcastinginduction

Add to favorites

Compare this product

Characteristics

- Configuration

- chamber

- Function

- melting, casting

- Heat source

- induction

- Other characteristics

- automatic

- Maximum temperature

385 °C, 1,200 °C, 1,600 °C

(725 °F, 2,192 °F, 2,912 °F)- Width

760 mm, 980 mm, 1,985 mm

(29.92 in, 38.58 in, 78.15 in)- Height

580 mm, 640 mm

(22.83 in, 25.2 in)- Depth

475 mm, 640 mm

(18.7 in, 25.2 in)

Description

HF Series High-frequency Induction Fusion Machine is mainly used to make sample preparation with glass fusion method for XRF and ICP analyses.

Models Available Configuration

HF3000 1 work station with 1 sample position, up to 1 sample per batch

HF3200 2 work stations with 1 sample position each, up to 2 samples per batch

HF3400 4 work stations with 1 sample position each, up to 4 samples per batch

HF3002 1 work station with 2 sample positions, up to 2 samples per batch

HF3202 2 work stations with 2 sample positions each, up to 4 samples per batch

HF3402 4 work stations with 2 sample positions each, up to 8 samples per batch

Features:

Advanced Configuration

1. Equipped with high-frequency induction heating device for rapid heating and cooling.

2. Touch screen designed for easy operation.

3. High-precision infrared temperature sensor with PID temperature control technology for accurate temperature control during the fusion process.

4. A heat-resistant ceramic protection device designed for the platinum crucible and the forming mould to prolong their service lives.

High Automation and Efficiency

1. Speedy sample preparation of about 5-10 mins per batch.

2. Automatic shaking and mixing to maintain the uniform fusion.

3. Fusion and casting into shape just with one button.

Improved Safety

1. Built-in ventilation system to exhaust harmful gases generated in the fusion process.

2. Multiple safety protection system, such as over pressure, overflowing, overheating, lack of water, and over temperature.

Catalogs

Other CKIC / Changsha Kaiyuan Instruments Co., Ltd products

EDXRF Analyzer & Pretreament

Related Searches

- Furnace

- Chamber furnace

- Electric furnace

- Heat treatment furnace

- Drying furnace

- Laboratory furnace

- Controlled atmosphere furnace

- Automatic furnace

- Melting furnace

- Air circulating furnace

- Compact furnace

- Electric resistance furnace

- Muffle furnace

- Metallurgy furnace

- Induction furnace

- Nitrogen furnace

- Calcination furnace

- Furnace for the food industry

- Casting furnace

- Moisture measurement oven

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.