- Hydraulics - Pneumatics

- Valve

- Relief valve

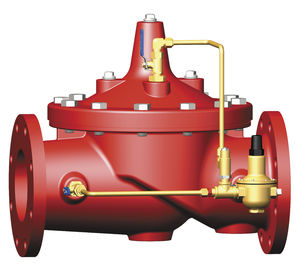

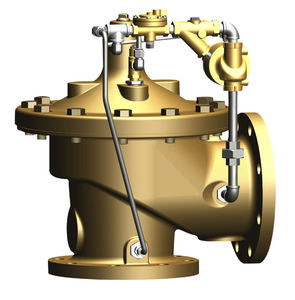

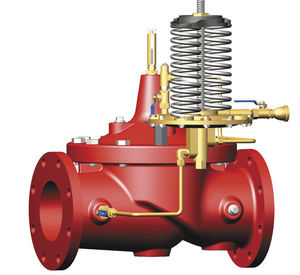

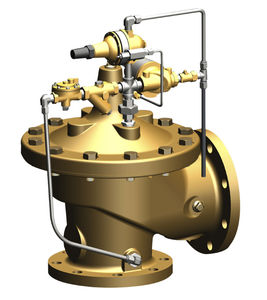

- CLA-VAL Automatic Control Valves

Relief valve 34 series

Add to favorites

Compare this product

Characteristics

- Controlled pressure

800 psi

- DN

Max.: 3 in

Min.: 0.5 in

- Flow rate

Max.: 50,000 us gal/min

(189,270.59 l/min)Min.: 0 us gal/min

(0 l/min)

Description

• Ductile Iron Body

• Stainless Steel Trim and Float

• Easily serviced without removal from pipeline

• Working pressures to 800 psi

• Engineered for drip tight seal at low pressures

Cla-Val Series 34 Air Release Valves are designed to vent entrained air

that collects at high points in a pipeline. This valve continuously

eliminates air from a system by releasing small quantities of air before

large air pockets can occur. In many installations, continuing

accumulations of air in the pipeline (lacking air release valves); cause

flow capacity to slowly decrease; power consumption slowly increases;

unnoticeable at first, until flow drops dramatically, even stopping due to

air blocks in the piping. Another problem resulting from excessive air

accumulation is unexplained pipeline rupture. These ruptures are

passed off as the result of ground settling or defective pipe, Where as

in reality its large air pockets that greatly increase pressure surges

(normally occurring) when flow stops and starts causing the rupture.

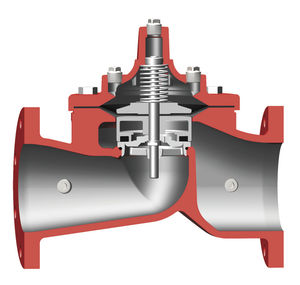

During normal pipeline operation, air accumulation at the high point will

displace the liquid within the air valve and lower the water level in relation

to the float. As level of the liquid lowers, where the float is no longer

buoyant, the float drops and opens the valve orifice seat and permitting

accumulated air to be exhausted to atmosphere. After air is released, the

liquid level in the air valve rises and closes the valve orifice seat. This

cycle automatically repeats as air accumulates inside the air release valve,

thereby preventing the formation of air pockets.

Catalogs

Cla-Val Waterworks Catalog

148 Pages

Other CLA-VAL Automatic Control Valves products

Fire Protection

Related Searches

- Valve

- Control valve

- Ball valve

- Water valve

- Pneumatic valve

- Electrically operated valve

- Regulating valve

- Flap valve

- Non-return valve

- Gas solenoid valve

- Normally closed solenoid valve

- Pneumatically-operated valve

- Pressure limiter

- Piston actuator valve

- Single-stage regulator

- Oil valve

- Industrial regulator

- Metal non-return valve

- Radial diaphragm valve

- Water solenoid valve

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.