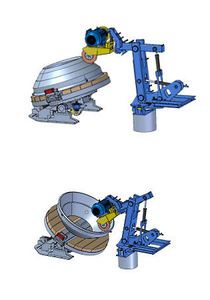

Manipulator with hook max. 20 tfor boom cranesarticulatedfor foundry applications

Add to favorites

Compare this product

Characteristics

- Gripping device

- with hook

- Applications

- for boom cranes

- Other characteristics

- articulated, for foundry applications

- Carrying capacity

10 t

(11 us ton)

Description

Clansman Dynamics manipulators operate in some of the toughest manufacturing environments in the world but continue to provide supremely robust, high-technology solutions for material handling in foundries, forges, steelworks and even garbage handling plants for energy conversion.

The design philosophy of Clansman Dynamics manipulators is simple - the equipment must be robust and reliable and specifically designed for the harsh environments that it works in, ultimately resulting in improved uptime, lower maintenance costs and smoother production. This is achieved through detailed modelling, analysis and stress testing by our in-house team of expert engineers. Our objective is to reduce and, where possible, eliminate fatigue and stress failures that are associated with the highly cyclical processes of production environments.

Clansman Dynamics has the world’s largest range of rail or statically mounted manipulators, offering capacities from 20 kg up to 20,000 kg. Each machine, regardless of size, can be offered with a wide range of options to suit customers’ requirements. Latest developments include highly flexible PLC control as an alternative to the traditional analogue PCB control card.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Clansman Dynamics‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.