Nozzle mix burner 1001gasmulti-fuelsolid fuel

Add to favorites

Compare this product

Characteristics

- Type

- nozzle mix

- Power source

- gas, multi-fuel, solid fuel

- Firing

- indirectly fired

- Applications

- for rotary kiln

- Other characteristics

- low-emission

- Power

Min.: 1,000,000 W

(3,412,140 BTU/h)Max.: 50,000,000 W

(170,607,000 BTU/h)

Description

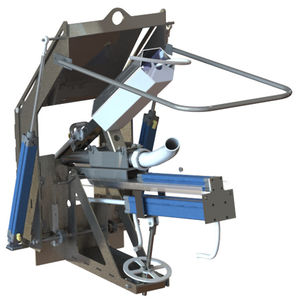

Clean Combustion's High Performance Rotary Kiln Burner systems have been designed for energy intensive industrial applications and will highly improve efficiency, simplify maintenance and lower emissions.

The dynamic technology supports solid, slurry, fluid and gas fuels, at single or multi-fuel operations within the same system. Our Rotary Kiln burners provide improved energy extraction, resulting in lower emissions, better cost efficiency and higher up-time compared to previous generations with outdated technology.

The combination of the vortex injectors, dynamic gas registers and a adjustable swirl turbulator gives the operator total control of the layout and position of the flame at different fuel flows and speeds. This helps to optimize the process and ensures a complete combustion of the fuel entering the zone, reducing fuel consumption and undesired exhaust particles.

Clean Combustion’s manageable design focuses on daily operations. Functions are easily accessible, the design is self-cleaning and maintenance is reduced and simplified.

Burner standard features

• Burner Management System (BMS)

• Burner Safety System (BSS)

• Igniter an pilot flame

• Flame scanner

• Actuators

• Flame shape control

• Local control panel

• Fuel Inlet connect

• Atomizing inlet connect

• Air inlet

• Junction box

Burner options

• Bio powder injection and feed systems

• Gas train

• Oil train

• Primary air station

• DCS connect

Liquid fuels

• Oil No. 1-6

• Tall oil

• HTF

• Methanol

• Ethanol

• Bio oil

Gas fuels

• Natural gas

• Biogas

• Producer gas

• LVHC

• SOG

• LPG

Catalogs

No catalogs are available for this product.

See all of Clean Combustion‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.