- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Steam boiler CBEX serieshot waternatural gasfuel oil

Add to favorites

Compare this product

Characteristics

- Product

- steam, hot water

- Power source

- natural gas, fuel oil

- Firebox

- fire tube

- Configuration

- horizontal

- Other characteristics

- industrial, two-pass

- Power

Max.: 1,864.25 kW

Min.: 74.54 kW

- Pressure

125 psi, 300 psi

Description

Highest operating efficiency of any scotch marine firetube boiler

Exclusive Cleaver-Brooks integral head burner with air-cooled front head

Hawk controls for maximum efficiency

Single source boiler, burner and control

Minimum excess air across the operating range

Small footprint

3 pass model includes an option for an integral pre-piped feedwater economizer

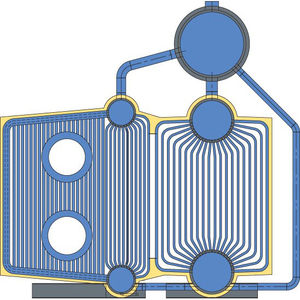

Using advanced engineering methods, design engineers designed the CBEX to optimize every component of the boiler, including the burner, the furnace, and the tubes, in order to provide optimally balanced heat release zones and minimizing thermal stresses in the boiler. Extended heat transfer tubes only found in EX systems uses Computational Fluid Dynamics (CFD) calculations to optimize the geometry of the tube and increase heat transfer by 85%. The result of the advanced heat transfer design is higher efficiency in a smaller footprint. Offered in a two-pass, waterback or dryback design, the CBEX boiler package is engineered for long life, highest part load (or operational) fuel-to-steam/water efficiency, maximum safety and lowest emissions. Its quiet operation, ease of maintenance and flexibility to add desired options further enhances the package. Integration of the core components is the key to the CBEX systems. The superior Hawk control allows the boiler to run at the absolute maximum efficiency. Reduce fuel use with the optional stack economizer by recovering waste heat from flue gases and using it to preheat boiler feedwater. The LevelMaster low-water cutoff and pump control is the safest control available.

APPLICATIONS

Process Steam

Industrial Process

Building Heat

Sterilization

Humidification

VIDEO

Catalogs

No catalogs are available for this product.

See all of Cleaver-Brooks‘s catalogsRelated Searches

- Gas burner

- Direct fired burner

- Steam boiler

- Hot water boiler

- Gas boiler

- Recovery unit

- Natural gas burner

- Nozzle mix burner

- Indirectly fired burner

- Smoke tube boiler

- Horizontal boiler

- Industrial boiler

- Electric boiler

- Energy recovery system

- Heaters burner

- Fuel oil boiler

- Heat recuperator

- Compact boiler

- Natural gas boiler

- Standard burner

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.