- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Thermal fluid boiler Max-Flow® hot watergashorizontal

Add to favorites

Compare this product

Characteristics

- Product

- thermal fluid, hot water

- Power source

- gas

- Configuration

- horizontal, vertical

- Other characteristics

- industrial, heat-recovery

- Power

Min.: 20,000,000 BTU/h

Max.: 200,000,000 BTU/h

- Pressure

2,300 psi

Description

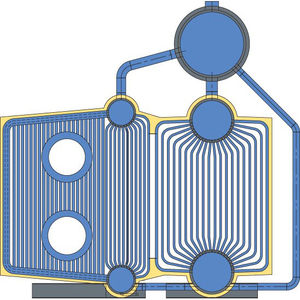

Fluid-cooled membrane wall construction.

Optimized flow pattern controls film temperature and local heat flux rates.

Combination of bare tubes and various degrees of finned tubes in a staggered or inline arrangement for optimized heat transfer and pressure drop.

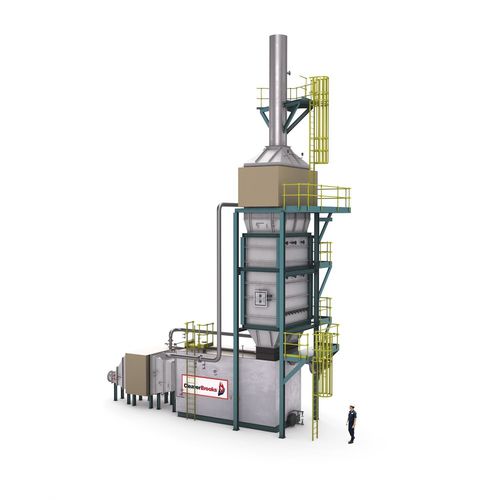

Horizontal or vertical outlet fits any space requirement.

Steel or aluminum casing, depending on your preference.

Custom-engineered design to accommodate space requirements.

Can accommodate selective catalytic reduction (SCR) and CO catalyst.

Max-Flow Thermal Fluid Heater (TFH) and High Temperature Hot Water (HTHW) generators are available for most applications ranging from 20-200 MMBTU/hr. They incorporate a fluid-cooled membrane wall construction for the furnace and heating coil enclosure, creating a highly efficient, shop-assembled package. They can be fitted with a register burner or designed to recover heat from turbine exhaust and supplemented with a duct burner, up to 2,800˚F. This is a highly-efficient forced circulation design that will last for years to come.

APPLICATIONS

Industrial Process

Building Heat

Hospital and Healthcare

Power and Utilities

Catalogs

Energy Recovery Solutions

16 Pages

Corporate Brochure

16 Pages

Related Searches

- Gas burner

- Direct fired burner

- Steam boiler

- Hot water boiler

- Gas boiler

- Recovery unit

- Natural gas burner

- Nozzle mix burner

- Indirectly fired burner

- Smoke tube boiler

- Horizontal boiler

- Industrial boiler

- Electric boiler

- Energy recovery system

- Heaters burner

- Fuel oil boiler

- Heat recuperator

- Compact boiler

- Natural gas boiler

- Standard burner

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.