Compact control Accu-Trimstand-alonefor boiler

Add to favorites

Compare this product

Characteristics

- Other characteristics

- compact, stand-alone, for boiler

Description

Stand-alone Oxygen trim control

Steam or hot water boiler control

Saves fuel

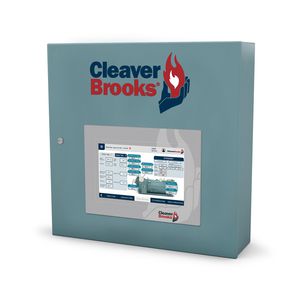

The Cleaver-Brooks Accu-Trim is a stand alone, O2 trim control package ideal for those systems without other high-end control requirements. Can be used on new equipment or applied to any boiler as a field retrofit or upgrade.

Stand-alone trim control

Air or fuel trim

Variable-speed drive option

Works with standard or Siemens gas trains

User-friendly setup

The Cleaver-Brooks Accu-Trim O2 Trim System is a stand-alone, PLC-based control system designed to maintain the proper fuel-to-air ratio of a boiler/burner. The system will automatically compensate for changes in temperature, barometric pressure, or fuel characteristics, as well as correcting for normal hysteresis. The system is intended for use with single-point positioning, or jackshaft-type, combustion controls; however, it may be customized for special applications such as parallel positioning or alternate fuel firing. A complete system includes oxygen and firing rate sensors, a control panel, which houses the PLC, and an actuator or VSD system, which trims either the fuel or airflow.

Design options include the custom C-B O2 Probe and industrial O2 probes such as Yokogawa. A variable-speed drive is used to provide fuel or air trim. The C-B Accu-Trim works with standard or compact fuel trains such as the Siemens valve assembly. Setup and operation are easy with the user-friendly HMI.

Catalogs

No catalogs are available for this product.

See all of Cleaver-Brooks‘s catalogsRelated Searches

- Building control system

- Temperature regulator control system

- Temperature control system

- Configurable control system

- Manual control system

- Compact control system

- Load control system

- Switch control system

- Integrated control system

- Remote control system

- Fuel control system

- Pump control system

- Automation control

- Level regulator

- Boiler control system

- Stand-alone control system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.