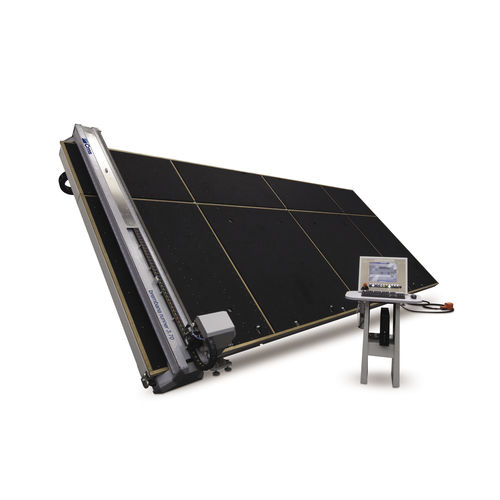

Glass cutting table runnerair cushion

Add to favorites

Compare this product

Characteristics

- Materials

- for glass

- Other characteristics

- air cushion

- Width

4,400 mm, 6,900 mm

(173 in, 272 in)- Length

2,600 mm, 3,350 mm

(102 in, 132 in)

Description

Runner is a tilting cutting table with three interpolated axes for straight and shaped cutting of flat glass plates with thickness ranging from 2 to 25 mm.

• - Electrical and electronic equipment are completely integrated in the machine’s basement. This solution saves floor space, assures a very easy diagnostic of potential errors, and provides the utmost airconditioning system (air-conditioning system optional)

• - Mechanical motorized tilting system of the work table makes it easy to load/unload glass sheets in small spaces and guarantees a long machine life, absolute reduction of maintenance and smooth movement.

• - High pressure turbine that generates an air cushion simplifying the handling of glass sheets; the air cushion can be set in two positions, depending on glass dimensions and thickness.

• - Cutting head completely engineered by CMS with automatic control of the cutting pressure depending on glass thickness and oil flow according to the cutting speed.

• - “C” axis included in the standard supply, guarantees the highest accuracy in shaped cuts.

FASTEST TILTING TABLE

The system for the overturning of type mechanical, with chain transmission, allows tipping times of less than 20 seconds. Unlike hydraulic systems, maintenance is zeroed.

NO SETTING TIME

Thanks to the patented four-head system for automatic management of cutting of different thicknesses, no manual operation is required. Each head carries a wheel that is specific for its thickness, guaranteeing zero stop times when changing the sheet.

COMPLETE REMOVAL OF THE LOW-E

The peripheral grinding wheel eliminates the low emissivity layer with speeds up to 80 m / min.

VIDEO

Catalogs

Related Searches

- Cutting system

- Metal cutting system

- CNC cutting system

- Cutting machine for industrial applications

- Automatic cutting system

- Knife cutting system

- High-precision cutting system

- Sheet metal cutting system

- Band sawing machine

- Plastic cutting system

- Sheet cutting system

- Cutting machine for the automotive industry

- Horizontal sawing machine

- High-performance cutting system

- Compact cutting system

- Rotary blade cut-off machine

- Bridge cutting system

- Precision sawing machine

- Cutting machine with automatic loader

- Plastic sawing machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.