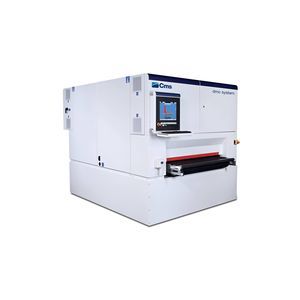

Finishing deburring machine dmc eurosystem mdedge roundingdeburringbelt

Add to favorites

Compare this product

Characteristics

- Associated function

- edge rounding, deburring, finishing

- Type

- belt

- Applications

- metal parts, for small parts

- Other characteristics

- CNC

Description

DMC Eurosystem md dry deburring finishing machines combine both top quality machining and system flexibility to meet a wide variety of production requirements. Based on a rich package of standard features and countless devices, this machine is the ideal solution for mid-sized modern and dynamic manufacturing companies.

• SAFETY

High adhesion effect conveyor belt combined with vacuum of work table allows the processing of small and thin workpieces.

• USER-FRIENDLINESS

Management and storing of working programs through color touch screen “Hydra V-Pad” control panel.

• MODULAR STRUCTURE

Flexible working unit placement offers solutions for any production requirement.

• RELIABILITY

High efficiency power transmission through the use of Poly-V drive belts (on working unit drive motors).

• PRODUCTIVITY

Abrasive belts length 2.620 mm for long life and working width 1.350 mm for wide or multiple machinable pieces.

• VERSATILITY

Quick tool change systems and extractable discs unit for fast replacement of abrasive discs.

UP TO 4 OPERATING GROUPS FOR TODAY'S AND TOMORROW'S NEEDS

Frame structure from 2 to 4 operating groups configurable to solve a wide range of dry applications. The versatility of the empty module allows the future installation of a new group, expanding the production capacity of the machine.

WIDE RADIUS: UP TO 2 mm EDGE ROUNDING

Double row of 17 counter-rotating vertical brushes able to offer unparalleled results of edge breaking and oxide removal (from thermal cutting). The group is fully extractable for a complete tool change in less than 2 minutes.

VIDEO

Catalogs

DMC eurosystem MD

13 Pages

DCM metal system

13 Pages

Related Searches

- Deflashing machine

- Metal parts deburring machine

- Brush roller deburring machine

- Edge rounding deburring machine

- Deburring deburring machine

- Finishing deburring machine

- Belt deburring machine

- CNC deburring machine

- Compact deburring machine

- Sanding deburring machine

- Small part deburring machine

- Edge sanding machine deburring machine

- Manual deburring machine

- Polishing deburring machine

- Manually-operated deburring machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.