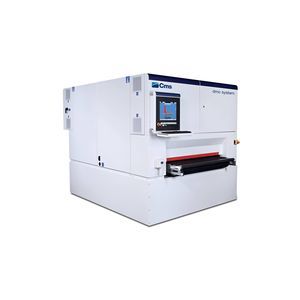

Finishing deburring machine dmc topmetaledge roundingpolishingmetal parts

Add to favorites

Compare this product

Characteristics

- Associated function

- edge rounding, finishing, polishing

- Applications

- metal parts

- Other characteristics

- CNC

Description

Dmc Topmetal is designed to meet all deburring and satinizing demands, including heavy-duty machining. Wet processing is ideal for customers requiring very high quality finishes such as preparation of surfaces for mechanical polishing, chrome-plating and other galvanising processes.

Dmc Topmetal contact rollers are available with a diameter of 250 mm or 320 mm. The latter, thanks to the larger contact surface with the workpiece being processed and greater ability to absorb any defects on the abrasive belt joint, are specifically indicated for all applications requiring very high quality finishes. The contact rollers are available in bare steel or with an oil and heat resistant rubber coating (with hardness from 20 to 85 shores). They are also fitted with a special helicoidal grooving, optimised to ensure proper cooling and to improve ejection of machining debris.

WIDE RADIUS: UP TO 2 MM EDGE ROUNDING

Exclusive planetary unit using gears, with disc brush rotation speed independent from the speed of the head, for a more effective deburring and edge rounding up to 2 mm even on plates larger than 1 meter.

UP TO 25% MORE PRODUCTIVITY

Contact rollers up to 320 mm diameter for a larger contact surface and damping of abrasive belt junction to guarantee a 25% higher productivity than smaller contact rollers.

SHINE FINISHING: THE BEST FINISHING FOR UNIFORMITY AND QUALITY

Batteries of 25 nozzles located before and after every working unit for a proper cleaning and cooling of the working area: this means surface finishes up to P2000 grit and greater lifetime of abrasive belts.

VIDEO

Catalogs

DMC topmetal

13 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.