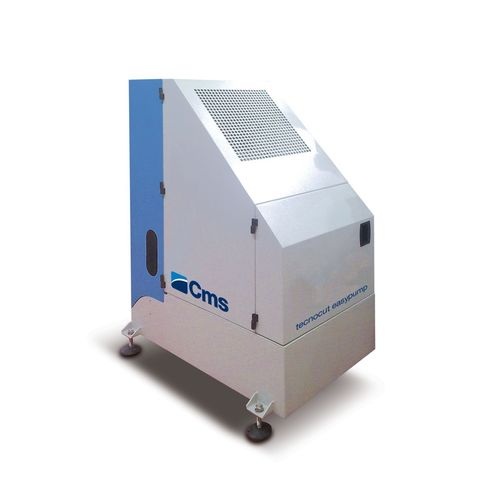

CMS has developed a new concept of high-pressure intensifiers: two or three parallel, independent and electronically synchronized pressure multipliers, which deliver a constant pressure while eliminating the need of an attenuator, a typical feature of old, traditional intensifiers.

highly constant pressure without using any attenuator

higher stability of the dynamic pressure signal to guarantee superior quality cut

lower wear of all machining centre high-pressure circuit components, longer duration of materials and reduction in maintenance interventions

the configuration with three independent cylinders allow to disable any one of them that requires maintenance, thus keeping the intensifier running and avoiding to shut down the cutting system

software-based electronic control of cutting pressure

hydraulic pump with fixed flow rate

hydraulic cylinders return circuit managed by nitrogen accumulators

water/Oil exchanger for hydraulic circuit cooling

specific for CMS cutting systems.

the 60HP model comes with 2 motors (in order to work 30+30 HP)

CONSTANT OUTPUT PRESSURE FOR BETTER CUTTING QUALITY

Hydraulic intensifier with 2 or 3 independent and electronically syncronized parallel cylinders to guarantee a constant signal of output pressure without the use of attenuator.

REDUNDANT ARCHITECTURE: LESS MACHINE DOWNTIME

The technology with 3 independent cylinders allows the bypass of a single cylinder that needs maintenance, while the machine is working, avoiding unnecessary downtime.