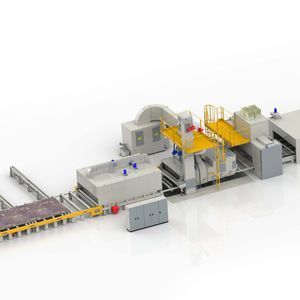

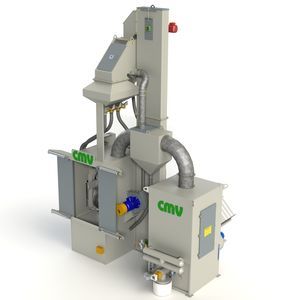

Suspended load shot blasting machine for metalautomaticturbine

Add to favorites

Compare this product

Characteristics

- Type

- suspended load

- Applications

- for metal

- Other characteristics

- automatic, turbine

Description

Suitable for blasting and shot peening of castings, forged, stamped, welded assemblies, etc. It can operate with steel shot and optionally with steel grit.

Features

• Built-in resistant steel.

• Works with fast production cycles.

• Reduces the blasting time.

• Guarantees a higher uniformity in the blasting parts, even in the more complex ones.

Component features

• Compact exhaustion system: it uses filters with a non-woven polyester cartridge. Equipped with automatic cleaning through the pulsing jet. Meet the main ambient standards.

• Exclusively patented blast wheels: reduce blasting time, being more productive than similar machines or even with an oscillating hook.

• Two service doors: with manual opening and structure welded over the bearing.

• Command panel: mounted in an armored enclosure, meets the standards for the sector and is equipped with a friendly interface.

Optional

• Blast wheel frequency inverter.

• Vibratory or rotative sieve.

• Tool steel lining to operate with steel grit.

VIDEO

Catalogs

No catalogs are available for this product.

See all of CMV‘s catalogsRelated Searches

- Blast machine

- Metal shot blasting machine

- Blast room

- Automatic blast machine

- Hand blast cabinet

- Manual shot blasting machine

- Pressure blast room

- Continuous shot blasting machine

- Belt shot blasting machine

- Turbine shot blasting machine

- Hook shot blasting machine

- Injector blast cabinet

- Automatic blast room

- Roller conveyor blast machine

- Rotating table shot blasting machine

- Blast cabinet for the automotive industry

- Compact blast machine

- Wet blasting cabinet

- Rugged blast cabinet

- Blast cabinet for medical applications

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.