- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

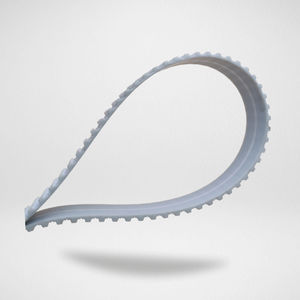

Timing belt STDpolyurethaneneoprene®industrial

Add to favorites

Compare this product

Characteristics

- Type

- timing

- Material

- polyurethane, neoprene®

- Sector

- industrial

- Width

Min.: 4 mm

(0.157 in)Max.: 200 mm

(7.874 in)- Pitch

Min.: 2 mm

(0.079 in)Max.: 14 mm

(0.551 in)

Description

STD profile synchronous belts offer significant advantages over standard synchronous belts. Their profile is designed to distribute forces over the entire belt tooth, dispersing critical stresses over a larger surface area. This reduces tooth shearing and extends belt life. STD profile synchronous belts are ideal for industrial applications requiring precise shaft synchronization. They are also an excellent alternative to V-belts and chain drives.

Conditions of use :

✔️ Belts must be correctly sized for the load and power they will have to support.

✔️ Belts must be compatible with the temperature conditions to which they will be exposed.

✔️ Belts must be correctly tensioned and aligned to ensure optimum operation.

✔️ Belts must be selected according to their maximum operating speed to avoid problems of slipping, overheating or premature deterioration.

✔️ Special lubricants may be required to reduce friction between teeth and improve transmission efficiency.

Application fields :

-Automotive industry

-Agriculture and forestry

-Motorcycle industry

-Manufacturing industry

-Etc...

Catalogs

Belts & Pulleys

171 Pages

Related Searches

- Power transmission belt

- Right angle gearbox

- Flexible shaft coupling

- Shafts coupling

- Hollow-shaft gearbox

- Industrial gear reducer

- Transmission chain

- Industrial power transmission belt

- Rubber power transmission belt

- Metal chain

- Plastic strip

- Transmission shaft coupling

- Roller chain

- Timing belt

- Sleeve shaft coupling

- Machinery gearbox

- Straight-toothed sprocket wheel

- PU belt

- V belt

- Medical device gearbox

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.