- Power Transmission - Mechanical components

- Mechanical Transmission

- Clamping

- CNC-STEP GmbH & Co. KG

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Mechanical clamp machiningsteelfixed

Add to favorites

Compare this product

Characteristics

- Type

- mechanical

- Applications

- machining

- Other characteristics

- steel, fixed

Description

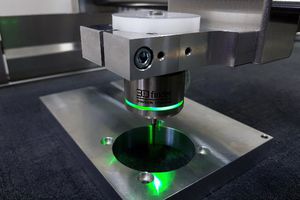

With this tool, you can easily and quickly clamp solid workpieces with different shapes on the T-slot plate or your grooving table. Firmly fixed, you can then machine the workpieces with the milling machine without slipping.

Our clamping claws made of bright drawn steel

The CNC-STEP steel clamp, provided with a 7mm wide slot and made of bright drawn steel, perfectly withstand the loads in our CNC machines’ application area.

What are clamps, and what are they used for?

Steel clamps are clamping elements provided with a hole and are used to fix various fixed workpieces, e.g. on a T-slot plate, which has to be connected precisely in the machining area of a CNC router. Another term for clamping claws is the designation clamping iron.

Besides, you can use these steel clamps also ideally for fixing pull-down vices on the T-slot plate. The clamps can be ideally positioned in the vice’s lateral clamping grooves and securely fastened in the work area.

Function

The Steel clamp is usually located at one end or at a corner of the workpiece to be machined. It rests with one end, usually the slightly bevelled or pointed end, on the material to be machined.

Note the horizontal position

At the other end of the steel clamp, a piece of solid material, which corresponds to the raw material’s thickness to be processed, is placed underneath to ensure that the clamping function can occur and that the clamping claws lie horizontally on the workpiece and cannot tilt.

Catalogs

No catalogs are available for this product.

See all of CNC-STEP GmbH & Co. KG‘s catalogsRelated Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.