- Machine-tools

- Cutting Tool

- Solid set of drill bits

- CNC-STEP GmbH & Co. KG

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Solid set of drill bits tungsten carbide

Add to favorites

Compare this product

Characteristics

- Type

- solid

- Drill bit material

- tungsten carbide

Description

Set of 10 solid carbide drills with polished flutes for best chip transport. Universally applicable.

for all materials

10 solid carbide drill bits with 1/8-inch shank

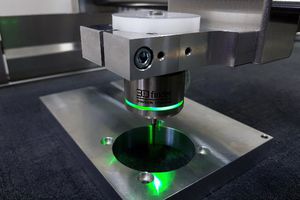

drill diameter mixed (as in the picture)

fast chip removal and excellent chip breaking due to specially developed cutting-edge geometries

high accuracy and stability

longer service life through tungsten carbide sintered carbide

self-centering

extremely sharp

also suitable for hard materials

Why solid carbide?

Solid carbide drill bits offer decisive advantages over conventional HSS tools. Besides a considerably higher rigidity of the tools and a long tool life is given. It provides the basis for high-speed milling or drilling and hard machining (HSC).

Only with solid carbide drills, it is possible to drill reliably and with long tool life even in hard materials.

What is the actual carbide?

In 1894, a French chemist discovered by chance (he was looking for a material to produce synthetic diamonds), the tungsten carbide, which becomes, together with cobalt, carbide through the sintering process.

Tungsten carbide is also known as tungsten carbide or sintered metal. It has a density of about 13-15g/cubic centimetre and becomes steadily harder, the finer the structure of the carbide is sintered and the more tungsten carbide it contains.

Tungsten carbide – micro-grain

Over the years, attempts have been made to reduce the grain size to obtain ever denser and harder structures. It has been successful until today.

Catalogs

No catalogs are available for this product.

See all of CNC-STEP GmbH & Co. KG‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.