- Industrial machines and equipment

- Printing, Marking and Engraving

- Carbide engraving tool

- CNC-STEP GmbH & Co. KG

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

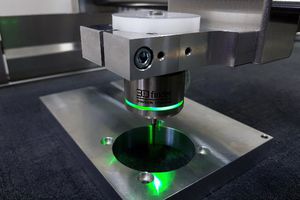

Carbide engraving tool

Add to favorites

Compare this product

Characteristics

- Material

- carbide

Description

The high-quality graver have a more precise free and relief grinding as well as sharper blades compared to cheap versions from China. Thus the engraving bits achieve much more accurate engraving results.

Fine machining works only with high-quality graver

A graver with a font width of 0.1 – 0.5mm, for example, has a free grinding of 0.03 – 0.15mm. The free grinding is located behind the blade and avoids the graver from rubbing with the material behind the blade. If not the graver would make bad engraving results because the blade doesn’t come into action properly. Moreover, the engraving bit would wear quickly.

The smaller the engraving diameter the more you need a premium graver

Products from the far east reveal deficiencies especially when it comes to fine machining. Most of the graver in the price range of 2 – 5 Euro cannot make high-quality engravings since milling motors with a true running accuracy of 0.02-0.05mm totally neutralise the fine grinding. In this case, you can only use a graver of 1.2mm width or wider because you can choose the free angle wider than it was the case with a graver with a small font width.

0,1-1,5mm font width

Various tip angle for

Aluminium

Brass

Steel

Plastic

Engraving stainless steel with a graver

For the precise engraving of stainless steel, the graver needs an additional coating to increase the service life. These tools are high-priced but they are worth the money because they make much more accurate engravings than cheap tools. In the long-term, you save a lot of money and nerves by using a solid carbide graver in your production process.

Catalogs

No catalogs are available for this product.

See all of CNC-STEP GmbH & Co. KG‘s catalogsRelated Searches

- Laser engraving system

- Wood engraving machine

- Glass engraving machine

- Metal engraving system

- CNC engraving machine

- Aluminum engraving system

- Stone engraving machine

- Marble engraving machine

- Brass engraving system

- Milling-engraving machine

- Engraving tool

- Plexiglas® engraving machine

- Photo engraving machine

- Carbide engraving tool

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.