- Machine-tools

- Machining Center

- 3-axis CNC milling machine

- CNC-STEP GmbH & Co. KG

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

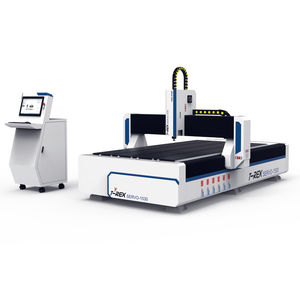

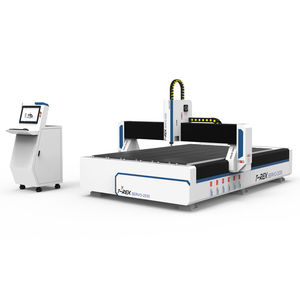

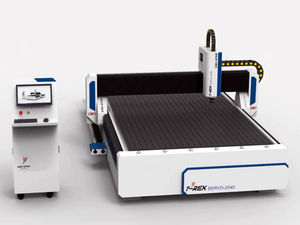

Gantry CNC milling machine T-Rex Servo-13253-axisverticalfor aluminum

Add to favorites

Compare this product

Characteristics

- Number of axes

- 3-axis

- Spindle orientation

- vertical

- Structure

- gantry

- Machined material

- for aluminum, for non-ferrous metals, for copper, for brass, for light alloys, for wood, for composites

- Associated functions

- drilling, engraving, chamfering

- Applications

- foam, for panels, for structures sandwich, for the mold industry, for the automobile industry, for molds, for the aeronautical industry, for profiles, for windows and doors, for small parts production, for large workpieces, for the aerospace industry, for small workpieces, for aeronautics, for aluminum profiles, for the aluminum industry, desk, for PVC window profiles, for window and door frames, for furniture, for the wood industry, for model making, for the plastics industry, for vehicles, for sheet metal, CAD/CAM

- Other characteristics

- high-speed, high-performance, high-precision, high-productivity, high-rigidity, with linear motor, for production, frame included

- X travel

2,500 mm

(98.43 in)- Y travel

1,300 mm

(51.18 in)- Z travel

200 mm, 300 mm, 400 mm

(7.87 in, 11.81 in, 15.75 in)- Work feed X-axis

50,000 mm/min

(33 in/s)- Work feed Y-axis

50,000 mm/min

(33 in/s)- Weight

1,600 kg

(3,527.4 lb)- Overall length

3,270 mm

(128.7 in)- Overall width

2,150 mm

(84.6 in)- Overall height

2,100 mm

(82.7 in)

Description

The portal milling machine T-Rex Servo was specially designed as a more powerful alternative to 2D, 2.5D and 3D material processing. Servo motors on all axes reduce the machining time of the working process and increase economic efficiency. Besides, the position monitoring of the servo motors guarantees an even safer machining process The large machining area, including placement aid, is ideally suited for industrial panel processing.

The servo motors router has high-quality HIWIN / THK / PMI linear guides and ground, helical toothed racks as well as high-performance planetary gears.

The optimised CNC router of the T-Rex series with servo motors now offers a faster and more efficient working process through advanced technology.

The bright and fresh design ideally complements the future-oriented servo motors, with which you can achieve maximum flexibility and high working speed and thus set new standards in your production.

Bellows and closed energy chains

Linear guides protected by bellows, linear carriages and racks on the X- and Y-axis, as well as the solid steel frame, make this servo motors router a durable and reliable CNC machine with servo motors for your production facility. The closed energy chains keep the cable harnesses clean and protected against external influences. Furthermore, the bellows protect the linear guides and prevent the racks from being clogged with chips and dust.

Servo motors router with precision racks and planetary gears

The T-Rex servo motor router is driven by helical, ground racks with planetary gears on the X- and Y-axis.

Catalogs

No catalogs are available for this product.

See all of CNC-STEP GmbH & Co. KG‘s catalogsOther CNC-STEP GmbH & Co. KG products

SERVO MOTORS ROUTER / THE NEW T-REX WITH SERVO DRIVE

Related Searches

- CNC machining center

- Vertical CNC machining center

- 3-axis CNC machining center

- Precision CNC machining center

- CNC milling machine

- Vertical CNC milling machine

- 3-axis CNC milling machine

- CNC router

- High-performance CNC machining center

- 3-axis router

- Gantry CNC machining center

- Wood router

- Aluminum CNC machining center

- Bridge CNC milling machine

- Precision CNC milling machine

- Plastic router

- High-precision CNC milling machine

- Metal router

- Aluminum CNC milling machine

- Aluminum router

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.