- Machine-tools

- Cutting Tool

- End mill

- CNC-STEP GmbH & Co. KG

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

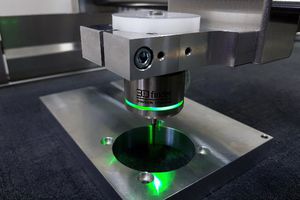

End mill solid carbidefor soft materialsfor plastics

Add to favorites

Compare this product

Characteristics

- Geometry

- end mill

- Construction

- solid carbide

- Treated material

- for plastics, for soft materials

Description

This one flute cutter is to use universal for milling softer plastics such as PVC, polyethene, Teflon, Forex etc. as well as for softer aluminium. It has a large flute for proper chip removal, which is essential and necessary, especially for incredibly soft materials!

Features of the one flute cutter:

one flute cutter

solid carbide

right twisted

Large chip flute for proper chip removal. Extremely sharp cutting edges.

The larger diameters have a drill tip, which automatically centres the tool when it plunges. Therefore, cutting or milling through with these one flute cutters is only possible on a corresponding sacrificial plate as a wear plate.

A coating is usually not economical with this type of one flute cutter, as any coating often also reduces the sharpness of the cutting edges, and it is the sharp cutting edges that are important for this type of end mill.

One flute cutters: Information on milling

For larger diameters with drill tip

The tool is automatically centred by the cutter tip when plunging in larger diameters. Thus, through-milling / through-cutting with these one flute cutters is only possible on a corresponding machining wear plate.

Makes a coated one flute cutter sense?

Experience has shown that coatings are not economical for this type of router. Because the sharpness of the cutting edges usually falls by the wayside due to any coating. Especially with a one flute cutter for soft materials, the extremely sharp cutting edges count. Accordingly, the quality of the milling results is given by this. Therefore, depending on the application, whether a coating of the milling cutter is worthwhile has to be decided.

Catalogs

No catalogs are available for this product.

See all of CNC-STEP GmbH & Co. KG‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.