- Materials - Tools - Components

- Standard Mechanical Component

- T nut

- CNC-STEP GmbH & Co. KG

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

T nut M6galvanizedfixed

Add to favorites

Compare this product

Characteristics

- Types

- T

- Material

- galvanized

- Other characteristics

- fixed

Description

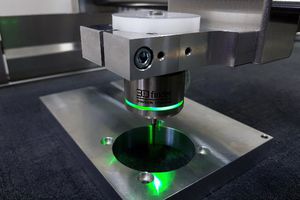

T-slot nuts are a popular clamping device and used to insert them into the grooves of existing T-slot plates, T-slot tables or clamping tables.

Nuts for T-slots are an essential accessory together with the T-slot table. Usually, the aluminium table has so-called T-slots according to DIN 650, into which you can insert the T-nuts for aluminium profiles. By sliding along the T-slots, you can bring them into the desired position and then screw into the alignment grooves of the fixtures. This small aid is used, for example, for fastening workpieces on a CNC router before the milling process. This type of fastening prevents the workpiece from slipping during machining.

How to use T-slot nuts?

When inserted into the clamping table slots, they are initially only loosely connected to the clamping table with a positive fit. A spring-mounted ball allows fixing the T-slot nut in any position. Due to their mostly centric arranged thread in different metric sizes (e.g. M8), screws of different lengths can now be provided with clamping claws or other clamping elements, stops and angle brackets. They are fixed directly on the clamping table to carry out mechanical machining in the form of milling etc. on the workpieces to be machined. On the one hand, you can usually use stops for exact alignment and use the clamping elements, in conclusion, to clamp the workpieces firmly on the machine table.

Our T-nuts can be used for several different aluminium profiles of various manufacturers. Please ask before you buy whether the T-slot nuts fit your profile (ITEM, BSO, Bosch etc.).

Catalogs

No catalogs are available for this product.

See all of CNC-STEP GmbH & Co. KG‘s catalogsRelated Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.