- Machine-tools

- Cutting Tool

- Chuck jaw

- CNC-STEP GmbH & Co. KG

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Chuck jaw

Add to favorites

Compare this product

Description

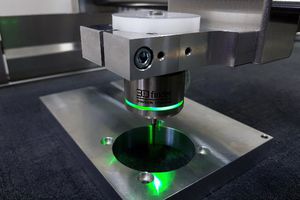

The four-jaw chuck contains an adapter/chuck flange for mounting on the RounDino 120 rotary axis with 80 mm diameter. With the rotary axis as 4-axis, our CNC machines become almost a CNC controlled lathe. At least you can mill parts round in connection with appropriate milling cutters.

Thread milling very simple up to M68 or even larger

You can also use the four-jaw chuck to produce external threads on round workpieces. All you need is the correct point angle of the milling cutter (for metric threads 60°). Accordingly, you will receive high-quality external threads up to a metric size of about M68 or even larger in no time at all. You can find a video about external thread milling with the milling machine here (unfortunately, this video is a little older).

Machining square and octagonal tubes

Just as you can centrally clamp a hexagon in a three-jaw chuck, square tubes can of course be milled quickly and easily with the four-jaw chuck. In conclusion, it is now possible to mill cut-outs or breakthroughs and drill holes all around the circumference of the square tube. Besides, you can of course also quickly clamp centrically octagonal workpieces and begin with the machining, for example on a CNC milling machine.

Small jaw chuck with extensive clamping range

Despite its small size, this four-jaw chuck has a considerable range when clamping externally or internally. In conclusion, this means that you can clamp workpieces up to 70 mm in the external clamping area and accommodate bores up to 63 mm in size in the inner area of the chuck.

VIDEO

Catalogs

No catalogs are available for this product.

See all of CNC-STEP GmbH & Co. KG‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.