- Robotics - Automation - Industrial IT

- Industrial Software

- CNC control software

- CNC-STEP GmbH & Co. KG

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

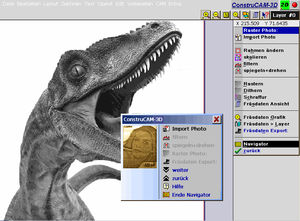

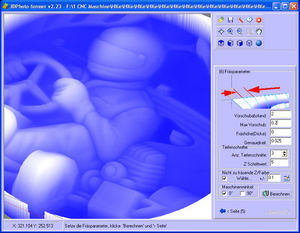

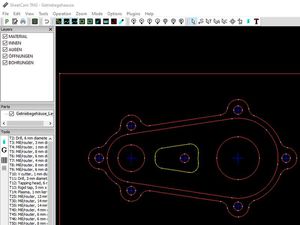

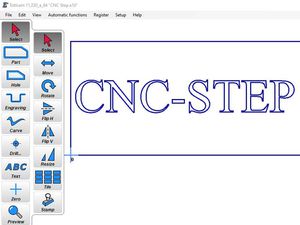

CNC control software WinPC-NC interface2D3D

Add to favorites

Compare this product

Characteristics

- Function

- interface, CNC control

- Type

- 3D, 2D

- Operating system

- Windows

Description

This shown drive is just a test presentation. The motors are on the verge of their load limit. In case of faster drive step loss would arise. Because of this fact we advise you to use a much lower traverse speed in the manual, so the motors can work without step loss and with a strong torque. The video just helps to demonstrate the stability of WIN PCNC with a giving of a high chopping frequency.

Detailed description about WIN PCNC Profi:

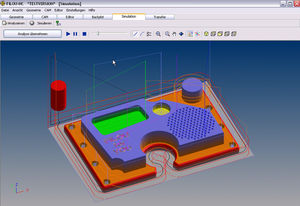

The software WinPC-NC is a software which will change any standard PC in conjunction with our axis-controller CNC-control into a universal NC-controller and governs 3 or 4 axis. The controller is necessary, because under Ms-Windows as multitasking operating system no or only reduced tasks on hard real time conditions can be implemented. This transfers the Achs controller in outstanding way.

For over 5 years WinPC-NC has been used hundreds of times successfully world wide and proves its reliability and precision in various applications on a daily basis.

Easy Start up

The NC-controller WinPC-NC and the axis-controller CNC-Control are already preconfigured at delivery and can be used without any problems. Connection between both components can be made with a zero-modem cable which is part of the delivery scope. Final performance stages of all axis and various additional signals are connected to controller CNC-Control. Except standard TTL-signals, also opto-decoupled input/output with 24V is optional possible. Interface assignment is done similarly to our other control-softwares. Modification from existing controls is therefore easily possible.

VIDEO

Catalogs

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.