- Products

- Catalogs

- News & Trends

- Exhibitions

Analysis software Flightpathqualityoptimizationprocess control

Add to favorites

Compare this product

Characteristics

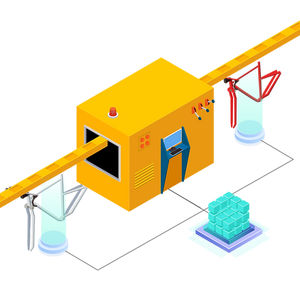

- Function

- analysis, quality, optimization, process control, cutting

- Applications

- process, flow

Description

With a few simple clicks, our software calculates the ideal settings for your reciprocator, considering the exact powder and piece being coated. Embrace accuracy and efficiency, effortlessly.

Not only does Flightpath save me time and effort, but it also helps me save on powder consumption. By optimizing the coating process, I have been able to reduce waste and increase cost-effectiveness in my operation.

Core Values

Powder Saving Efficiency

Flightpath's advanced AI algorithms analyze coating processes to optimize powder consumption, resulting in significant material savings.

By precisely determining the optimal settings, coatingAI also predicts exactly how much powder is saves, encuring applied efficiently, reducing waste and cutting costs.

Analytical Precision

Flightpath's AI-driven analysis provides a comprehensive understanding of coating processes, enabling operators to make data-driven decisions.

Flightpath identifies potential issues, predicts outcomes, and recommends adjustments, such as distance, speed, reciprecator height and reciprecator speed - ensuring consistent and high-quality coatings. This analytical precision eliminates guesswork and minimizes errors, leading to improved process control and enhanced productivity.

Level up Homogeneity

Flightpath's AI-powered optimization ensures a high level of homogeneity in coating applications. By considering factors such as part geometry, environmental conditions, and coating material properties, Flightpath recommends optimal settings for voltage, powder flow rate, and atomizer air pressure.

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.