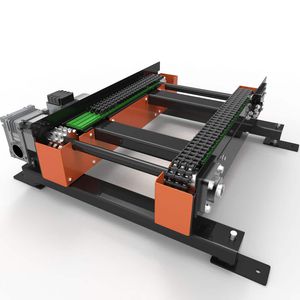

V-type conveyor belt B seriesstainless steelcarbon steelzinc-plated steel

Add to favorites

Compare this product

Characteristics

- Type

- V-type

- Material

- stainless steel, carbon steel, zinc-plated steel

- Sector

- industrial, for the food industry

- Applications

- for small parts, bulk products

- Other characteristics

- for heavy loads, with rollers

- Width

Max.: 1,500 mm

(59.06 in)Min.: 60 mm

(2.36 in)- Length

Max.: 12,000 mm

(472.4 in)Min.: 300 mm

(11.8 in)- Maximum load

10 kg, 20 kg, 100 kg

(22.046 lb, 44.092 lb, 220.462 lb)

Description

Belt conveyors offer a system of continuous transport formed by a band that is dragged by friction between the driving drum and the band itself.

This type of conveyors are used mainly to transport food, industrial, agricultural materials … Its most common application is for the transport of granulometric product or of small dimensions whose transport is not feasible by other systems such as roller transport.

B10

• The motorization is carried out by means of a gear motor or a drum motor, resulting in a more compact design in this case.

• Noise level: low

• Ø Driving drum: 60 to 120 mm

• Ø Tensioning drum: 60 to 120 mm

• Motorization: central or head

• Height adjustable leveling feet ± 50mm

Belt Conveyors offer a continuous physical support of the transported product , therefore, it is a suitable means when it comes to transporting granular or small material or in cases where greater stability of the transported product is required.

B20

• Ø Driving drum: 80 to 120 mm

• Ø Tensioning drum: 80 to 120 mm

• Motorization: central or head

• Adjustable handrails

• Height adjustable leveling feet ± 50mm

• Noise level: low

B24

• Noise level: low

• Ø Driving drum: 80 to 120 mm

• Ø Tensioning drum: 80 to 120 mm

• Motorization: in head

• Height adjustable leveling feet ± 50mm

B30

• Ø Driving drum: 80 to 120 mm

• Ø Tensioning drum: 80 to 120 mm

• Motorization: in head

• Height adjustable leveling feet ± 50mm

B60 Z

• Ø Driving drum: 80 to 120 mm

• Ø Driving drum: 80 to 120 mm

• Motorization: in head

• Height adjustable leveling feet ± 50mm

• Its constructive form allows easy integration into existing or new lines.

• Low noise level.

Catalogs

No catalogs are available for this product.

See all of Codimar S.L.‘s catalogsRelated Searches

- Rail conveyor

- Transporting conveyor

- Belt conveyor

- Horizontal rail conveyor

- Conveying belt

- Conveyor for the food industry

- Roller rail conveyor

- Industrial conveyor belt

- Inclined conveyor

- Drag chain conveyor

- Stainless steel conveyor

- Materials handling conveyor

- Transfer chain

- Conveyor roller

- Modular conveyor

- Conveyor belt for the food industry

- Pallet rail conveyor

- Discharge conveyor

- Curved rail conveyor

- Metal conveyor chain

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.