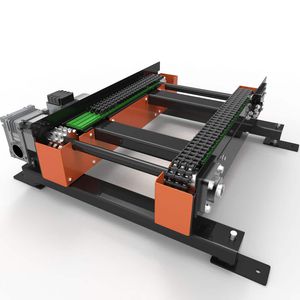

Hinged belt conveyor M serieswire meshchainfor the food industry

Add to favorites

Compare this product

Characteristics

- Technology

- hinged belt, wire mesh, chain

- Sector

- for the food industry

- Transported product

- for pallet

- Other characteristics

- modular, for heavy loads, height-adjustable, for lifting, stainless steel, light-duty, high-temperature

- Maximum load

20 kg

(44.092 lb)- Speed

Min.: 3,000 mm/min

(1.97 in/s)Max.: 4,000 mm/min

(2.62 in/s)- Effective width

Min.: 60 mm

(2 in)Max.: 1,500 mm

(59 in)

Description

Modular or metallic mesh and hinge conveyors are a type of machinery recommended for continuous transport of light loads.

It is also possible to use it to transport heavy loads such as pallets. For hinges, by increasing the number of branches, and for modular mesh by selecting a suitable chain as well as its sliding base.

They allow the change of direction of the transport flow, are easily cleaned, allow fluid drainage and some, such as metal mesh, are able to withstand high temperatures, allowing their use in an over or their environment.

They are suitable for food transport and with the use of accessories can be applied for lifting.

M10

• Its constructive form allows easy integration into existing or new lines.

• Noise level: low

The use of this machine is recommended for light load transport that require a continuous and stable support surface. Allows direction changes in the transport flow. Thanks to its design, it allows fluid drainage and easy cleaning.

M20

• Motorization: In head

• Noise level: low

The use of this machine is recommended for the transport of light loads that require a continuous and rigid base. It allows direction changes in the transport flow . Thanks to its design, it allows fluid drainage and its easy cleaning. Its constructive form allows easy integration into existing or new lines.

M30

• Noise level: low

It is used in work areas where the temperature of the product or the environment is high as in ovens Continuous conveying surface.

M40

• Length: According to installation

• Useful width: According to the product to be transported

Catalogs

No catalogs are available for this product.

See all of Codimar S.L.‘s catalogsRelated Searches

- Rail conveyor

- Belt conveyor

- Conveying belt

- Conveyor for the food industry

- Roller rail conveyor

- Industrial conveyor belt

- Drag chain conveyor

- Stainless steel conveyor

- Materials handling conveyor

- Transfer chain

- Conveyor roller

- Modular conveyor

- Conveyor belt for the food industry

- Pallet rail conveyor

- Discharge conveyor

- Curved rail conveyor

- Metal conveyor chain

- Loading conveyor

- Straight conveyor

- Inclined conveyor

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.