- Industrial machines and equipment

- Surface Treatment

- Hard anodizing

- Collini Holding AG

- Products

- Catalogs

- News & Trends

- Exhibitions

Hard anodizing aluminumtitaniumindustrial

Add to favorites

Compare this product

Characteristics

- Type

- hard

- Type of substrate

- aluminum, titanium

- Applications

- industrial

- Other characteristics

- with coloring

- Certifications

- ISO 14001

Description

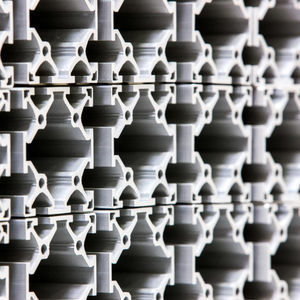

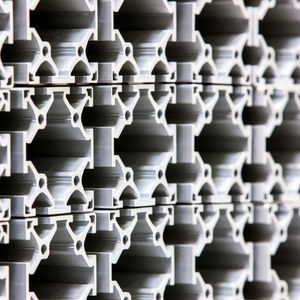

In contrast to the conventional galvanising process, no foreign metallic cover layer is applied during anodising. Instead, the surface of a light metal component is converted into an oxide layer by the galvanising/anodising process.

Since the oxide layer develops from the base material, the dimensional increase is only 50-55%. The remainder grows into the base material, which results in good adhesion to the base. Collini anodises aluminium (also known as Eloxal) and titanium. The anodising layers are hard, corrosion and wear resistant, and they have a good electrical and thermal insulating effect. Special anodising methods are offered for tribological systems.

Fields of application include all areas in which aluminium with increased technical specifications is required. For components made of titanium, there is an option for bio-compatible colour coding, which is particularly relevant for use in medical technology.

Typical components

Housings, fuel pumps, pistons, brakes, cooling systems, insulation components, couplings, valve controls, rail car doors, seat parts, suspensions, shock absorbers, ship parts, insulation and cooling units, façades, interior design, lights, window and frame profiles, guide rails, pistons, prostheses, kitchen appliances

Related Searches

- Anodic oxidation

- Aluminum anodic oxidation

- Anodic oxidation with coloring

- Nickel plating

- Painting

- Painting on metal

- Powder coating

- Zinc-plating

- Hard anodizing

- Galvanizing

- Automotive anodic oxidation

- Hot dip galvanizing

- Industrial anodizing

- Medical anodizing

- Metallization

- Chrome plating

- High phosphorus nickel plating

- Steel nickel plating

- Titanium anodizing

- Aluminum nickel plating

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.