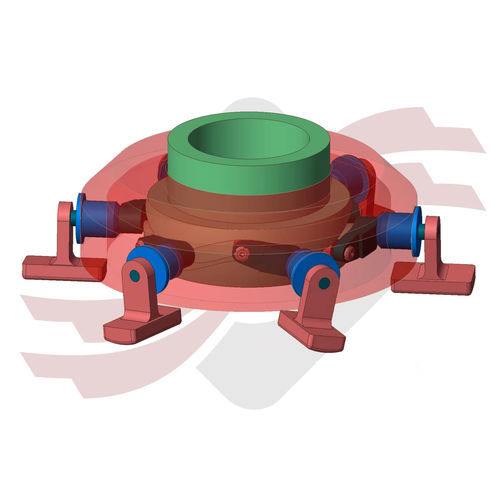

The Spheroconical Cam can be considered a development and an optimization of the Cylindrical cam. In the pictures below the functioning principles of a Cylindrical (fig.1)and Spheroconical cam (fig.2) are schematically shown

The basic difference between a Spheroconical and Cylindrical Cam is in the orientation of the follower in the follower’s wheel (C). In the Cylindrical Cam the follower’s axis is parallel to the output rotation axis while in the Spheroconical Cam the follower’s rotation axis (C) will always pass through the intersection between the Cam rotation axis (B) and the output rotation axis (A)

In the Spheroconical cam, unlike the Cylindrical cam commonly used, the contact surface between the follower and the cam’s profile is constant, using the whole height of the follower. In the Cylindrical cam the height of the contact surface varies during the rotation. For this reason the engineers must increase the diameter of the Cylindical cam to obtain a better contact, but the compactness and the speed of the machine is reduced.

The contact between the cam profile and the follower does not create any axial sliding movement so the friction is reduced and:

▪ efficiency is increased

▪ reliability is increased

▪ lifetime is increased

▪ operating speed is increased

▪ maintenance is reduced