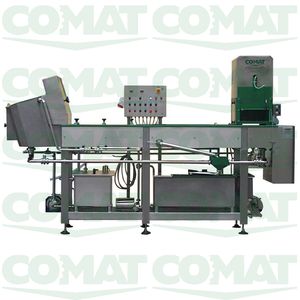

Stretching line MF10AV

Add to favorites

Compare this product

Description

This machine for continuous stretching through steam and reels is composed by 5 working sections:

1. SECTION OF FEEDING AND CUTTING OF RAW MATERIAL

In this section, the curd blocks are inserted in the hopper of the conveyor, and thanks to the advancing auger, the curd achieves the cutting machine mounted in the upper part of the conveyor, where the curd is cut with adjustable thickness. The curd will arrive, for falling, at the cooking section.

2. SECTION OF COOKING AND BUTTERMILK EVACUATION

During the passing in the cooking compartment, the curd is invested by a jet of water in exit by taps, for its pre-cooking. The adjustment of water temperature is managed by user, in order to obtain products with different degree of stretching and moisture.

3. SECTION OF HEATING OF STRETCHING LIQUID

Is equipped of automatic system for water heating, composed by an apparatus of thermoregulation, which controls the steam inlet in according to desired stretching temperature. The water heating is done through a direct input of steam through injector.

4. SECTION OF STRETCHING WITH REELS

In this section, the mass receives the right degree of fibrousness, thanks to the action of the stretching tools (couple of reels), which have adjustable speed.

Furthermore, is possible to adjust the moisture degree through input of stretching water in the cheese mass, with flow ajustable manually.

Catalogs

No catalogs are available for this product.

See all of Comat‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.