- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

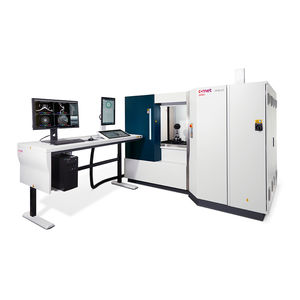

X-ray inspection system UX503D2Dcomputed tomography

Add to favorites

Compare this product

Characteristics

- Technology

- X-ray, 3D, 2D, computed tomography

- Operational mode

- automatic

- Type

- for quality control

- Applications

- for the automotive industry, for the aerospace industry

- Product applications

- for large parts

- Other characteristics

- non-contact

Description

With its large inspection envelope, multiple field-of-view extensions, and a powerful 450 kV X-ray tube, the UX50 takes the inspection of complex, dense parts to the next level.

• Wide application range: 450 kV and large inspection envelope

• Choice of line and/or flat-panel detectors for maximum flexibility

• CT techniques for extended field of view and image processing

• Simple creation of inspection sequences with Geminy

• Automated detector calibration and image sharpness measurements

• For applications e.g., in automotive, metal casting, and additive manufacturing

Maximum flexibility for quality assurance testing

Whether its massive motor blocks, larger steel parts, or complex e-mobility components – the Comet Yxlon UX50 CT system scans the most challenging items in record time. Fast switching between line and flat-panel detectors, intuitive operation with the user interface Geminy, and a comprehensive set of image processing tools make the UX50 ideal for an unlimited range of X-ray and CT applications in the industrial environment.

One system, two detectors: line detector and/or flat-panel detector

The UX50 offers a variety of detector configurations to meet the individual inspection needs of manufacturers. While CTScan 3, a line detector array (LDA) designed and produced by Comet Yxlon, is highly efficient at high energies, the Y.Panel 4343N offers more versatility. The configuration with both detectors provides the best solution for each task, allowing for quick and easy switching between the image chains in one sequence.

VIDEO

Catalogs

UX50

7 Pages

Other Comet Yxlon GmbH products

Powerful X-ray and CT inspection systems

Related Searches

- Xylon inspection system

- Xylon automatic inspection system

- Quality inspection system

- Xylon X-ray inspection system

- Defect detection inspection system

- Visual inspection system

- 3D inspection system

- Inspection system for the packaging industry

- Xylon inspection system for the automotive industry

- Quality control inspection system

- 2D inspection system

- Computer-controlled inspection system

- Inspection system for the electronics industry

- Manual inspection system

- High-resolution inspection system

- Xylon computed tomography inspection system

- Inspection system for the aerospace industry

- Large part inspection system

- Non-contact inspection system

- Tire inspection system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.