- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

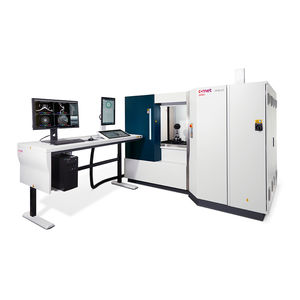

X-ray inspection system Cheetah EVO CTautomatedquality

Add to favorites

Compare this product

Characteristics

- Technology

- X-ray, CT

- Operational mode

- automated

- Type

- quality

- Applications

- for the automotive industry, for the electronics industry, for the aerospace industry

- Other characteristics

- computer-controlled

Description

The Cheetah EVO is designed to meet the demands of Industry 4.0, enabling efficient and reliable inspection in the SMT and semiconductor industry as well as in laboratories.

• Reliable, fast, and repeatable inspections – manually and automatically

• Automatic void calculation with VoidInspect

• Easy-to-use, dynamic enhancing filters, e.g., eHDR

• Best available laminography with micro3Dslice and FF CT software

• Dose reduction kit, dose monitoring, and low dose detector mode for sensitive components

• Optional new water-cooled X-ray tube for a stable focal spot

• Optional high load capacity (< 20 kg)

The optional water-cooled FXT 160.51 X-ray tube

Inspectors know the problem: long scan times often lead to image distortions and question test repeatability due to labile results. It's an effect caused by the rising temperature of the tube housing and the target, which can lead to focal spot drift. The new water-cooled X-ray tube counteracts this phenomenon. It provides reliable heat dissipation and ensures a stable focal spot and crystal-clear X-ray images even after long beam times. You achieve reliable inspection results for the first scan just as for the umpteenth and can rely on the repeatability of the X-ray inspection at any time.

VIDEO

Catalogs

CY_Cheetah-EVO_Brochure_EN

7 Pages

Cougar EVO

7 Pages

Other Comet Yxlon GmbH products

Powerful X-ray and CT inspection systems

Related Searches

- Xylon inspection system

- Xylon automatic inspection system

- Quality inspection system

- Xylon X-ray inspection system

- Defect detection inspection system

- Visual inspection system

- 3D inspection system

- Inspection system for the packaging industry

- Quality control inspection system

- Xylon inspection system for the automotive industry

- Computer-controlled inspection system

- 2D inspection system

- Manual inspection system

- Inspection system for the electronics industry

- High-resolution inspection system

- Xylon computed tomography inspection system

- Inspection system for the aerospace industry

- Non-contact inspection system

- Large part inspection system

- Semiconductor inspection system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.