- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

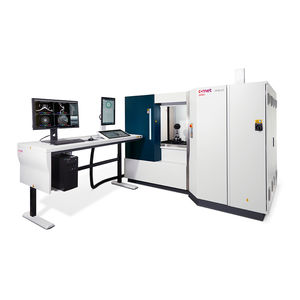

X-ray inspection system Cougar EVO3D2DCT

Add to favorites

Compare this product

Characteristics

- Technology

- X-ray, 3D, 2D, CT

- Operational mode

- automatic, manual

- Type

- quality control

- Applications

- for the automotive industry, for the electronics industry, for the aerospace industry

- Other characteristics

- high-resolution

Description

No need to waste floor space: the Cougar EVO is the smart system for efficient and reliable inspection in the SMT and Semiconductor industry as well as in laboratories – all on only one sqm.

• Reliable, fast, and repeatable inspections – manually and automatically

• Automatic void calculation with VoidInspect

• Easy to use, dynamic enhancing filters, e.g., eHDR

• Best available laminography with micro3Dslice and FF CT software

• Dose reduction kit and low dose detector mode for sensitive components

• Smallest footprint available on the market

Future-ready for the demands of Industry 4.0

In today’s smart factory, everything revolves around connectivity and self-optimizing processes. Industry 4.0 demands quality control systems that offer improved automated inspections and can become an integral part of the production line. Based on customer input, Comet Yxlon upgraded the Cougar EVO system with advanced features to deliver new heights in speed, image quality, reliability, repeatability, and a footprint of only one sqm.

Inspection capabilities: outstanding. Footprint: only one sqm.

With its compact dimensions, the Cougar EVO is the perfect choice for X-ray inspection in SMT, the semiconductor industry, and laboratories. Designed as a solution for facilities with space limitations, it combines minimum size and maximum performance. The weight of the Cougar EVO makes it suitable for many standard building floors. In addition, its size and weight make bringing the system into the location quick and hassle-free. In many cases, the existing elevators can be used for transport.

Catalogs

Cougar EVO

7 Pages

Other Comet Yxlon GmbH products

Powerful X-ray and CT inspection systems

Related Searches

- Xylon inspection system

- Xylon automatic inspection system

- Quality inspection system

- Xylon X-ray inspection system

- Defect detection inspection system

- Visual inspection system

- 3D inspection system

- Inspection system for the packaging industry

- Quality control inspection system

- Xylon inspection system for the automotive industry

- Computer-controlled inspection system

- Manual inspection system

- 2D inspection system

- Inspection system for the electronics industry

- High-resolution inspection system

- Xylon computed tomography inspection system

- Inspection system for the aerospace industry

- Non-contact inspection system

- Large part inspection system

- Semiconductor inspection system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.