- Products

- Catalogs

- News & Trends

- Exhibitions

Laser diffraction particle size analyzer CMA seriesprocessmultichannelfor integration

Add to favorites

Compare this product

Characteristics

- Technology

- laser diffraction

- Applications

- process

- Other characteristics

- particle size distribution, for integration, multichannel

Description

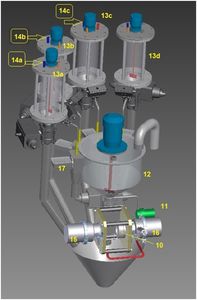

Particle analysis ranging from 0.5-800 microns in multiple parallel channels. Typically the measurement is carried out in parallel for 9 channels.

How it works?

The particle size measurement system is based on the laser diffraction principle. Special multi-particle scattering model is used to provide reliable measurements with very high concentrations of particles. This allows measuring particle sizes directly in most of the production lines. Pneumatic valve system is employed for switching between the measured channels. The system can switch channels in free combination, duration and priorities

The Multi Channel System for particles size measurements consists two main parts:

Main unit cabinet located on production area

Control PC located in control room

Both are connected by two cables Ethernet or RS-485.

Key benefits

current particle size distribution curves

average particles size distribution curves displayed with the specified averaging duration

calculated particle volume

calculated Blaine

concentration of particles in the measuring channel

trend curves showing ROI like d50, d75, d97 etc

graphs and tables showing specified curve parameters

possibility to store all measurements locally and in the external systems through the OPC server

possibility to control the external devices by PID controllers to allow constant production control

Catalogs

No catalogs are available for this product.

See all of Comex‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.