- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Adhesive dispensing system vacuumtwo-componentmanual

Add to favorites

Compare this product

Characteristics

- Product

- adhesive

- Other characteristics

- automatic, robotic, manual, vacuum, two-component

Description

IN COLLABORATION WITH THE RESEARCH AND DEVELOPMENT OFFICE OF ITS CUSTOMERS, COMI DESIGNS AND MANUFACTURES HIGHLY AUTOMATED WORKING UNITS FOR SPRAYING RESINS USED TO REINFORCE THERMOFORMED PLASTIC PARTS

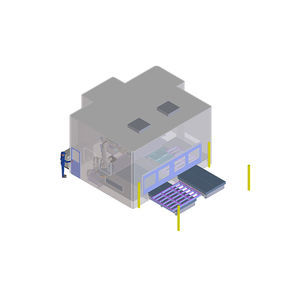

This working unit has been designed to spray reinforcing / insulation polyurethane foams on specially designed templates.

Machine structure

The structure of the machine guarantees maximum operator safety

Fully closed cabin, completely closed by perimeter walls and steel roof

Automatically operated front doors and manual side access door

Protection of the working area outside the cell with photoelectric barriers.

Working table

The project is customized to promote high accessibility and flexibility in the management of workpieces:

System with rotating tables or slide-through tables, which allow the loading/unloading of pieces in masked time

System with fixed tables, with the possibility of translating inside the unit in the case of pieces higher than the robot’s reach

Pumps for vacuum application aimed at clamping the pieces on the templates

Spraying and milling units

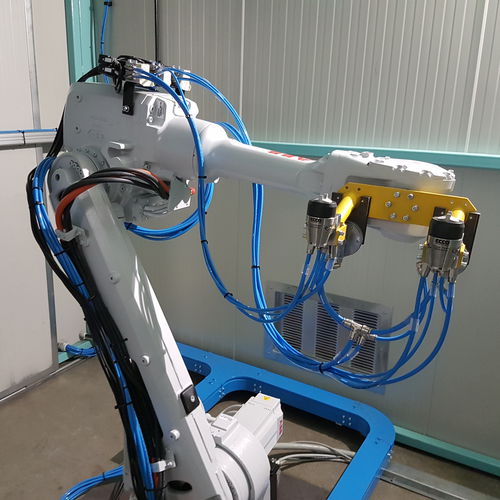

The cell sprays two-component resins through an operating unit consisting of:

High pressure machine for dispensing

Automatic mixing head

Pipes, tanks and loading pumps, kits for dehumidifying materials drums, and other accessories

Robot & software

6-axis anthropomorphic robot

Mounted on the ground on a fixed platform or on a moving carriage

Robot control unit

Software for programming the robot

COMI is able to provide turn-key working units which integrate systems and equipment such

Catalogs

No catalogs are available for this product.

See all of COMI GROUP‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.