- Detection - Measurement

- Force Measurements

- Cost-effective weigh module

- A&D COMPANY, LIMITED

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

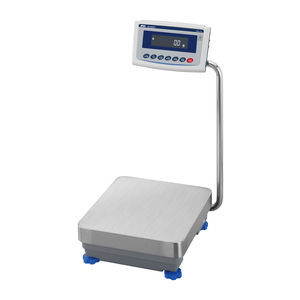

Digital weigh module AD-4212C seriescost-effectiveweighing

Add to favorites

Compare this product

Characteristics

- Options

- digital, cost-effective

- Applications

- weighing

Description

Have you faced these problems of production-line weighing systems?

- Weighing is slow.

- Instruments take up space.

- Weighing sensors do not last long.

- Display units are redundant.

- Cabling is complex and expensive.

The AD-4212C, a high precision electromagnetic weighing sensor with an integrated A/D converter, is the way to solve such problems.

Firstly, the stabilization speed is extremely fast. It is less than 0.5 seconds with a resolution of 1 mg (up to 30 g + tare), or 1.3 seconds with a resolution of 0.1 mg (up to 51 g + tare).

Secondly, the size is highly compact, with the width being only 59 mm. It is ideal for installation in narrow spaces.

Thirdly, the AD-4212C boasts high durability and accuracy over time. In our test using the AD-4212C-300 (320 g × 1 mg), the product easily withstood 30 million repeated loadings, and the final span drift value was a mere 5 digits (5 mg). Moreover, the AD-4212C incorporates our patented shock absorber under the weighing pan. It copes with movement in all directions, protecting the sensor from actuator malfunctions.

Fourthly, since the AD-4212C outputs digital weighing data directly to a panel computer, PC, or PLC, whether to add a display unit is completely up to you.

Finally, with the optional AD-8923-CC or AD-8923-BCD remote controller, it is possible to transmit data using CC-Link or BCD, in addition to displaying the weighing results, changing response speed, and performing calibration.

There are six models in the AD-4212C Series, all of which are IP65 dust and waterproof, and come with free WinCT-4212C software.

VIDEO

Catalogs

Related Searches

- A&D Company load cell

- A&D Company tension/compression load cell

- A&D Company steel load cell

- A&D Company digital scale

- A&D Company strain gauge load cell

- A&D Company stainless steel load cell

- A&D Company weighing load cell

- Digital panel meter

- A&D Company stainless steel scale

- A&D Company beam type load cell

- A&D Company platform scale

- Panel-mount panel meter

- A&D Company scale with LCD display

- A&D Company compression load cell

- A&D Company weight indicator

- Industrial weighing scale

- A&D Company waterproof scale

- A&D Company digital weight indicator

- A&D Company electronic scale

- IP67 force transducer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.