Electrical contact with wire springs fingercopper

Add to favorites

Compare this product

Characteristics

- Options

- with wire springs, finger

- Material

- copper

Description

Spring finger contacts (SMT)

Materials

Beryllium Copper or alloy, stainless steel, gold for local surface treatment.

MANUFACTURING PROCESS

Cutting and folding using automated press and cutting machines. Thermal treatment process for mechanical resistance.

Prototyping

With soft tooling for the validation stage.

Options

Local surface treatment. Detailed mechanical and material report (young modulus, cycles of compression, etc.)

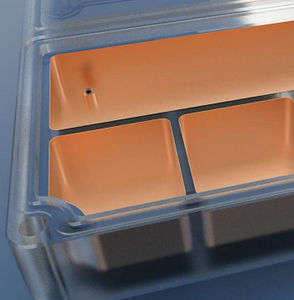

Packaging

Bulk, thermoformed tray or reels for pick and place (automation).

Description

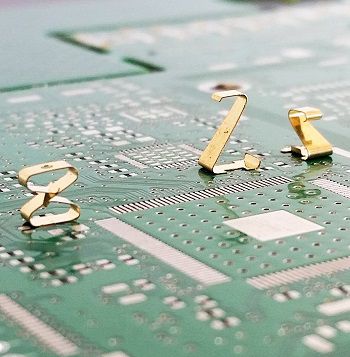

These types of contacts (SMT or bulk, standard or custom) provide a flexible connection for ground contact.

Especially used as: battery contact, antenna contact and on PCBs.

They can be assembled by pick and place (SMT process).

Our design department can analyze the mechanical design requirements before proposing any type of SMT metal contact in your application.

Catalogs

No catalogs are available for this product.

See all of Compelma‘s catalogsRelated Searches

- Electrical connector

- Data electrical connector

- Metal electrical connector

- Polymer connector

- Polymer seal

- Cable connector

- Metal seal

- Insulation connector

- Flat gasket

- Gold connector

- Silicone gasket

- Stainless steel gasket

- Nickel connector

- Electrical contact

- Graphite gasket

- Compression gasket

- Flexible gasket

- Shielding gasket

- Wire electrical contact

- Composite gasket

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.