Composite material gasket graphitealuminumsilicone

Add to favorites

Compare this product

Characteristics

- Material

- graphite, composite material, aluminum, silicone

- Application

- EMI shielding

- Other characteristics

- conductive, flexible, extruded

- Pressure limit

3,500,000 Pa, 4,300,000 Pa, 8,500,000 Pa

(507.6 psi, 623.7 psi, 1,232.8 psi)

Description

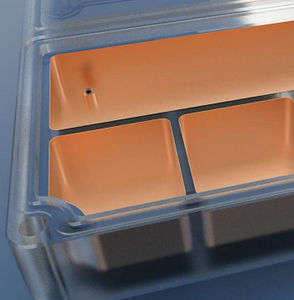

Bi-material gaskets

Materials

Silicone, fluoro silicone, loaded particles (aluminum, copper, nickel, graphite).

MANUFACTURING PROCESS

extrusion, molding, splicing.

Hardness

Ask for specific hardness

Options

Several standard profiles or possibility of specific gaskets, Anti-stretch

Packaging

EMI sealed bags

Description

Bi-material gaskets ensure a conductivity along the gasket and an efficient sealing against fluids.

These gaskets are manufactured using silicone or fluorosilicone and a second silicone material loaded with conductive particles.

Both materials are extruded simultaneously.

The conductive silicone partially covers the gasket section.

This process makes the bi material gasket resistant and flexible.

Several gasket profiles are available. This type of gasket is used very efficiently for IP sealing and emi shielding over time.

Our range of bi material gaskets is developed to withstand the corrosion and aging problems encountered in aggressive environments: salt spray, electrolytic agents, oil, and solvents.

Catalogs

No catalogs are available for this product.

See all of Compelma‘s catalogsRelated Searches

- Polymer seal

- Metal seal

- Flat gasket

- Plastic absorber

- Silicone gasket

- Stainless steel gasket

- Graphite gasket

- Flexible gasket

- Compression gasket

- Shielding gasket

- Urethane absorber

- Metal gasket

- Composite gasket

- EMI shielding gasket

- Conductive gasket

- Metallic fastener

- Steel fastener

- Extruded seal

- Aluminum gasket

- Silver gasket

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.