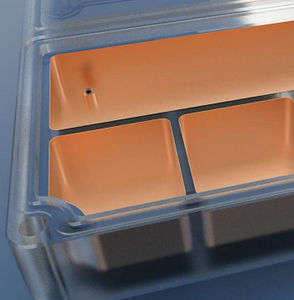

High-frequency absorber urethanefoam

Add to favorites

Compare this product

Characteristics

- Material

- urethane, foam

- Other characteristics

- high-frequency

Description

High frequency and microwave absorbers

Materials

Urethane, silicone, nitrile, neoprene (with or without adhesive).

MANUFACTURING PROCESS

Molding, impregnated foams, on-line injection.

Particle load

Material are charged following the frequencies to absorb.

Prototyping

Die cutting or custom cut

Hardness

Depending of the material

Options

Cutting on drawing, adhesive, complexing with other materials like insulator, aluminum strip.

Packaging

Reel, sheet, bulk (depending of the size and of the quantity)

Description

Absorbent materials are used for electromagnetic insulation andelectromagnetic emission absorption by Joule effect.

Several materials are available: wide range absorption foam, absorber orelastomer base absorbers with low thickness and frequency tuned.

Our range products are specifically offered for:

LF (Wireless charge, induction)

HF (RFID, NFC)

VHF (radio)

UHF (RFID, Lora, Sigfox, telecom)

SHF (Telecom)

We support you to choose the best absorber for your application.

For SHF and higher frequencies absorption, it is better to choose a full metallicpart for electromagnetic shielding.

Depending on the absorption level required, the absorber can be really thin(0,1mm).

Might be packaged in reel for automatization.

Catalogs

No catalogs are available for this product.

See all of Compelma‘s catalogsRelated Searches

- Polymer seal

- Metal seal

- Flat gasket

- Plastic absorber

- Silicone gasket

- Stainless steel gasket

- Graphite gasket

- Compression gasket

- Flexible gasket

- Shielding gasket

- Urethane absorber

- Composite gasket

- Metal gasket

- EMI shielding gasket

- Metallic fastener

- Conductive gasket

- Steel fastener

- Extruded seal

- Aluminum gasket

- Silver gasket

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.