- Metrology - Laboratory

- Metrology and Test Equipment

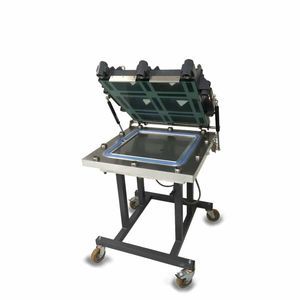

- Flow testing machine

- Composite Integration Ltd

Flow testing machine XM-5104manualfor panelsvacuum

Add to favorites

Compare this product

Characteristics

- Test type

- flow

- Operating mode

- manual

- Test material

- for panels

- Technology

- vacuum, thermocouple, by air injection, PID

- Other characteristics

- stainless steel, vacuum

Description

Both mould halves include oil/water heating channels or integral electrical heating with appropriate insulation.

The appropriate peripheral shim plate is used to define the panel cavity thickness. The mould seals between the top faces of the shim plate and the bottom faces of the shim plate.

The mould is mechanically clamped using bolts, and is limited to use at low pressures up to 4 bar (G).

Both mould halves are designed to maintain accuracy at positive pressures.

Injection is via a peripheral injection gate with a central vent.

The upper mould is hinged and supported with gas-struts for ease of operation.

Heating:

Oil/water heating is recommended for heating up to 150°c (see option 08)

Electrical heating is recommended for heating up to 180°c. Two options are available for electrical heater control (see options 09 & 11)

Note: Protective insulation will be required for moulds operating above 50°c, option 13 will need to be specified if going above this temperature.

Water/oil heating unit comprising:

Supplied with stainless steel braided hoses

Temperature control unit with digital display of the set and actual temperature with 1/10 Degree to read in °C or °F

Heating switchable in stages, from 3kW oil operation to 9kW water operation

Heating capacity: 9kW water operation, switchable in stages 3,6,9kW. 3kW oil operation

Pump capacity: Motor 0.75kW

Power Supply: 400V 50Hz 32A 3P+N+E

Electrical Heating: Standard control unit comprising:

PID temperature controller with K type thermocouple feedback from mould

Control system to comprise all necessary electrical safety and gear control including backup overtemperature protection system

Catalogs

No catalogs are available for this product.

See all of Composite Integration Ltd‘s catalogsOther Composite Integration Ltd products

Test Panel Tooling

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.