- Products

- Catalogs

- News & Trends

- Exhibitions

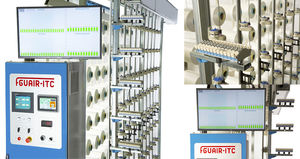

Direct warper ENEVO

Add to favorites

Compare this product

Characteristics

- Type

- direct

Description

COMSAT’s extensive experience in the field of weaving preparation, has allowed the creation of direct warper ENEVO.

Ease of use, versatility and high quality are the starting points of the new direct warper ENEVO. It presents a series of innovations, obtaining a maximum warp quality and high efficiency with the goal of always offering the maximum performance.

Maximum efficiency

Warping speed of ENEVO warper offers a high efficiency and productivity.

Beam self-centering

The hydraulic shifting of the beams has a self-centering system as well as an automatic beam doffing device.

Pressing device

The contact pressing cylinder is driven by a hydraulic system that allows adjusting the contact force depending on the yarn to be worked.

This device has a quick backward movement and braking to avoid friction with the yarn during machine stops.

Zigzag reed with oscillation

The zigzag reed allows warping with several yarn densities without need to make any new yarn passages, easily and quickly from the central machine control. Furthermore, this device is equipped with oscillation and reed antiwear system for a perfect warping quality, extending the life of the reed.

Anti yarns crossing device

To avoid yarn breakage by yarns crossing between the reed and the output cylinder, the anti yarns crossing device acts automatically during acceleration of the machine.

Combination with FGV V-TENS

The combination of ENEVO direct warper with FGV V-TENS single end tensioning device ensures high quality beams.

Warp-stop motion integrated with single end tensioning device.

Pretensioning system with tension compensation due to the length of the creel.

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.