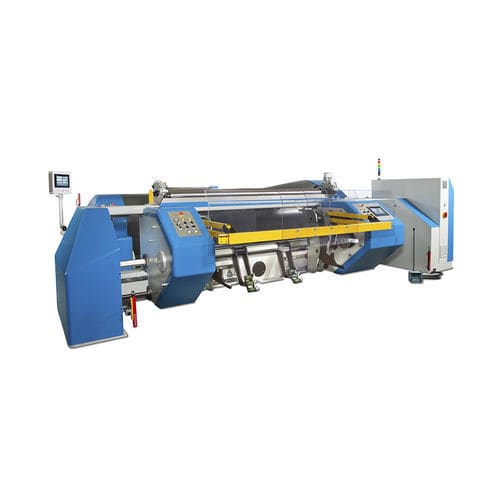

The weaving preparation sector is changing, moving more towards value-added fabrics. Recognized by the versatility of their machines, COMSAT presents TECMAT, the warper that can successfully meet any type of application.

Technology combined with the experience gained in the course of three generations is the starting point of TECMAT, allowing our customers to obtain the highest performance and productivity with the simplicity of operation that characterizes our machines

Maximum productivity and versatility in warping

Maximum productivity during the warping process with the widest range of yarns.

New architecture of construction

Designed with maximum strength and rigidity to offer reliability during the whole warping and beaming processes.

Automatic warp section tension control

The automatic warp section tension device, guarantees an identical length and tension of the yarns independent of the bobbin diameter and the warping speed.

• Allows speed changes at any time during the warping process.

• Keeps the tension constant during the acceleration and stop of the machine.

Automatic feed system

Completely automatic feed determina-tion, without the need for any previous calculation or the need to introduce parameters with regard to the yarn nature.

Together with the evener roll, identical warp sections with the same diameter are obtained.

New design of the reading cylinder without gravity effect to obtain more precise readings. Optionally, installation of a laser reading system to determine the automatic feed without any contact with the yarn.