- Products

- Catalogs

- News & Trends

- Exhibitions

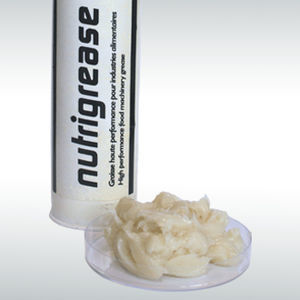

Lubricating grease multipurposemaintenancewith calcium soap

Add to favorites

Compare this product

Characteristics

- Function

- lubricating, multipurpose, maintenance

- Composition

- with calcium soap

- Product applications

- for bearings

- Field

- for agricultural applications

- Other characteristics

- high-temperature, high-performance, multi-purpose, multi-use

- Operating temperature

Max.: 130 °C

(266 °F)Min.: -20 °C

(-4 °F)

Description

Multi-purpose greases are recommended for most maintenance applications where the temperature remains within a conventional range of -20°C to 130°C. Load, speed and lifetime constraints also remain within standard values.

Multi-purpose greases are called traditional or conventional greases. They are recommended everywhere when constraints remain “moderate”. Mostly offered in NLGI2 grade, the most versatile: The archetype being EP2 Grease. These are the greases with the best price/performance ratio and they have proved their worth over a long time.

As their name indicates, they are very versatile. They are suitable for all types of general lubrication. Targeted additives and the know-how of manufacturers-formulators have nevertheless made them very good challengers for speciality greases.

They cover all application fields, or nearly all, and are available in all sorts of packaging:

from the 400g cartridge, which remains the most common small format

up to 190kg drums

According to the industry, these multi-purpose greases can be offered in boxes, buckets or kegs and also aerosols and automatic greasers.

Applications

Multi-purpose or multi-functional greases are particularly suitable for lubrication of equipment such as:

Axles and articulations

Gimbals, chassis

Pipes (for their protection)

...

Characteristics

Multi-purpose greases can be made of calcium soaps (hydrated or anhydrous) but more generally they are made of a lithium soap. This chemistry is particularly stable and resistant to mechanical constraints.

Exhibitions

Meet this supplier at the following exhibition(s):

Related Searches

- Synthetic lubricant

- Synthetic oil

- Anti-corrosion lubricant

- Mineral lubricant

- Bearing lubricant

- High-performance lubricant

- Industry oil

- High-temperature lubricant

- Mineral-based oil

- Gear lubricant

- Bearing grease

- High-performance oil

- Anti-corrosion oil

- Metal lubricant

- Long-life lubricant

- Universal lubricant

- Metal oil

- Metal aerosol spray

- High-temperature oil

- Chain lubricant

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.