- Products

- Catalogs

- News & Trends

- Exhibitions

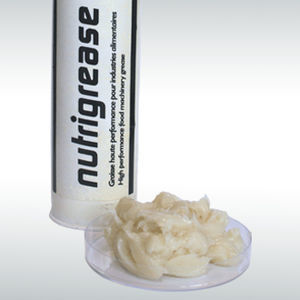

Lubricating grease protectivesyntheticmineral

Add to favorites

Compare this product

Characteristics

- Function

- lubricating, protective

- Composition

- synthetic, mineral, graphite

- Product applications

- fitting, for filtration

- Other characteristics

- high-performance, biodegradable, high-viscosity

- Operating temperature

1,000 °C

(1,832 °F)

Description

Greases intended for lubrication and protection of drill pipe threads, threads and fittings subject to high tightening torques. Grease technologies developed for mine drilling or water drilling.

The range of greases for drilling is specially designed to meet the specific needs of the exploration industry. CONDAT offers a wide range of greases with a high content of dry (or solid) lubricants. They help to avoid risk of seizure and ensure easy disassembly.

The grease becomes a vector to uniformly disperse the solid lubricants and thus deposit them specifically in the zones to be lubricated.

These greases always have a strong resistance to water wash-out and a very high level of adherence even on wet surfaces.

Applications

Treatment of threads on pipes and fittings

Coring

In-the-hole drill

Rotary

Characteristics

The nature and content of solid lubricants ensures lubrication adapted to the pressure and friction constraints found in these industries.

Mineral or synthetic oils for every type of use.

Soaps meeting implementation temperatures

Exceptional welding load resistance, can exceed 800kg

Anti-seizure, anti-rust and anti-corrosion additives

Product benefits

This range of drilling greases meets the demands of numerous and varied applications. They are used by specialist drilling companies

Easy implementation

Environmental requirements taken into account

Effective even at extreme temperatures (>1000°C according to the solid lubricant)

Protection of parts and easy disassembly.

BIONATUR DRILL, a biodegradable grease according to the OECD, shows a remarkable advance, combining a high level of performance with respect for the environment.

Related Searches

- Synthetic lubricant

- Synthetic oil

- Mineral lubricant

- Anti-corrosion lubricant

- Bearing lubricant

- High-performance lubricant

- Industry oil

- High-temperature lubricant

- Mineral-based oil

- Gear lubricant

- Bearing grease

- High-performance oil

- Anti-corrosion oil

- Metal lubricant

- Long-life lubricant

- Universal lubricant

- Metal oil

- High-temperature oil

- High load capacity lubricant

- Metal aerosol spray

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.