- Robotics - Automation - Industrial IT

- Industrial Software

- CMMS software

- Condition Monitoring and Protection

Machine condition monitoring software System 1'smonitoringdatabaseprocess control

Add to favorites

Compare this product

Characteristics

- Function

- monitoring, database, optimization, diagnostic, process control, scheduling, for machine condition monitoring

- Applications

- machine

- Type

- real-time

- Deployment mode

- online

Description

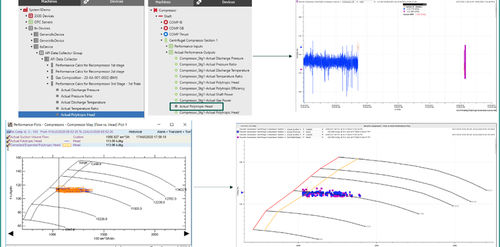

System 1's Performance as part of your overall condition monitoring platform, helps monitor asset performance and efficiency and enables performance diagnostics for better maintenance strategies.

Bently Performance when added to your System 1 installation provides insights into:

• Equipment efficiency changes over time and likely causes

• Overall production efficiencies and the potential impact on revenues

• Maintenance scheduling

System 1's Bently Performance Module

The Bently Performance software module extends functionality of System 1 to include online monitoring of thermodynamic performance. The module fully integrates with the System 1 database and display modules to give users access to comprehensive mechanical and thermodynamic machine-condition information.

Bently Performance executes calculations based on ASME PTC codes, producing key performance indicators:

Actual performance: Actual output for current ambient and operating conditions. This information also indicates the effect of deviation of machine operation from design condition.

Expected performance: Expected output as per OEM curves at design conditions. These values can be compared with actual performance if the machine is operating at the design condition specified by the OEM.

Corrected actual performance: Actual output transposed to standard day conditions (ISO or site-specific rating). When trended, they depict the relative degradation with respect to time.

Corrected expected performance: Expected output transposed to actual operating conditions. These values can indicate conditions like surge or stall.

Catalogs

No catalogs are available for this product.

See all of Condition Monitoring and Protection‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.