Eccentricity measurement system CU11 Seriesoptical3Dwire

Add to favorites

Compare this product

Characteristics

- Measured physical value

- eccentricity

- Technology

- optical, 3D

- Measured material

- wire, bearing

Description

- When Perfect is the Only Option

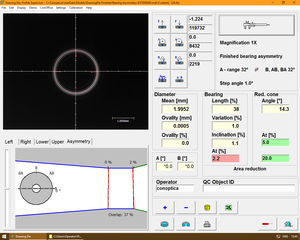

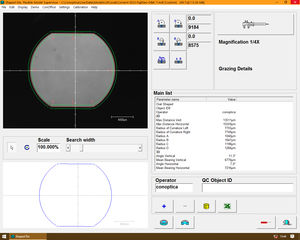

With the CU11 series Conoptica is breaking new ground in the field of drawing die measurement. For the first time, it is possible to produce an objective bearing asymmetry measurement. Up to now the only option has been to use a microscope with a skilled operator to assess whether the bearing was symmetric or not. With the CU11 series, operators have access to both inclination and variation data, a feature unique to the Conoptica CU11.

Bearing Asymmetry

In the ideal world, the bearing of the drawing die is a perfect cylinder, with straight sides and parallel top and bottom. The real situation is usually a different story, as the bearing can be inclined, have variation in the length around the die, or a combination of the two. With the CU11 you will be able to measure these parameters, and thereby gain new knowledge of your production process – whether you’re drawing wire or manufacturing drawing dies.

Choose your capacity

Some customers measure many dies per day, others measure fewer. We now offer the CU11 in 3 different versions to match the differences in required capacity, all with the same accuracy and range specifications. In addition to the regular CU11, customers can also choose the CU11X or the CU11S.

While the CU11 is already providing fast and accurate measurements, the CU11X is 50% faster, while the CU11S is 100% faster than the CU11X. This means that when using a CU11S, a full 3D Bearing Asymmetry measurement can be made faster than a single profile measurement on a regular CU11! The implications for the CU11S user are that full control of the 3D profile asymmetry has become a practical tool for everyday use.

Related Searches

- Measuring device

- Measuring machine

- Optical measuring machine

- Parts measuring machine

- Distance measuring machine

- Control measuring machine

- Diameter measuring machine

- Geometry measuring device

- 3D measuring machine

- Length measuring machine

- Rugged measuring machine

- Process measuring device

- Camera measuring device

- Cable measuring machine

- Wire measuring machine

- Profilometer measuring machine

- Small part measuring machine

- Machine tool measuring device

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.