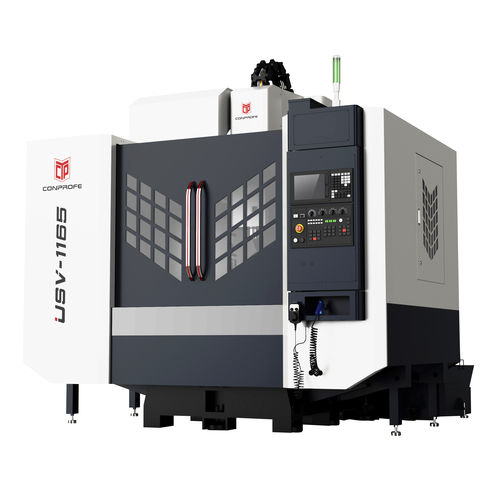

Ultrasonic CNC machining center USV-11653-axisverticalwith fixed portal

Add to favorites

Compare this product

Characteristics

- Number of axes

- 3-axis

- Spindle orientation

- vertical

- Structure

- with fixed portal, with moving table, column type

- Machined material

- for aluminum, for steel, for copper, for cast iron

- Spindle mount

- BT 40, BBT40

- Number of tool stations

- 24 tools

- Associated functions

- milling, tapping, chamfering, cutting, drilling

- Applications

- for the automobile industry, for titanium, for large workpieces, heavy-duty, for the aeronautical industry, for large-diameter parts, for aeronautics, for molds, for aluminum profiles, for heavy loads, deep hole, for heavy-duty machining, for the mold industry, for profiles, for the steel industry, for cast iron, for the aluminum industry

- Other characteristics

- high-performance, HSC, high-precision, high-rigidity, ultrasonic, high-productivity, high-power, single-head, wide, medium-sized

- X travel

1,100 mm

(43.31 in)- Y travel

650 mm

(25.59 in)- Z travel

600 mm

(23.62 in)- Rotational speed

12,000 rpm

(75,398 rad.min-1)- Power

11 kW, 15 kW

(14.96 hp, 20.39 hp)- Work feed X-axis

36,000 mm/min

(24 in/s)- Work feed Y-axis

36,000 mm/min

(24 in/s)- Table load capacity

800 kg

(1,764 lb)- Tool weight (max)

8 kg

(17.6 lb)- Positioning accuracy

0.01 mm

(0.00039 in)- Repeatability

0.007 mm

(0.00028 in)- Tool-changing time

1.6 s

- Weight

7,200 kg

(15,873.28 lb)- Overall length

2,760 mm

(108.7 in)- Overall width

3,000 mm

(118.1 in)- Overall height

3,100 mm

(122 in)

Description

Conprofe Ultrasonic green machining center--USV series include small and medium-sized specifications. After one clamping of the workpiece, the machine tool can automatically, efficiently and continuously complete the processing of various processes such as milling, drilling, boring, expanding, reaming, countersinking, and tapping.

It is suitable for the production of small and medium-sized boxes, plates, discs, valves, shells, molds and other complex parts, and the green machining technology is widely used in precision parts, 3C products, hardware, auto parts, medical equipment and other industries.

It has a highly rigid body structure and is equipped with high-end mechanical and electrical accessories, a precision control system, high-precision line rails and lead screws. The high dynamic response of the machine tool can realize high-speed cutting.

Overview

Fixed-column type with cross slide mechanism, large-span herringbone column, fully enclosed protection design, high-strength cast iron material for basic large parts, to meet the requirements of high rigidity and stable accuracy.

Tool magazine: The tool magazine with 24 tool positions is equipped with a tool arm, and the tool-to-tool changeover time is 1.5s.

Chip removal: Slope design at the bottom of the machine tool with built-in automatic flushing chip removal device; rear design of the water tank.

Spindle: Front-end labyrinth structure, with central air blowing device/function, all spindles adopt high-speed direct-connected spindle units.

Exhibitions

Meet this supplier at the following exhibition(s):

Related Searches

- Conprofe machining center

- Conprofe vertical machining center

- Conprofe 3-axis machining center

- Conprofe precision machining center

- CNC milling machine

- Conprofe 5-axis machining center

- Vertical CNC milling machine

- Conprofe high-precision machining center

- 3-axis CNC milling machine

- Conprofe rigid machining center

- Conprofe high-performance machining center

- Conprofe gantry machining center

- Conprofe high-rigidity machining center

- Conprofe milling machining center

- Conprofe high-productivity machining center

- Conprofe column type machining center

- Conprofe cutting machining center

- Conprofe aluminum machining center

- Conprofe machining center with pallet changer

- Precision CNC milling machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.