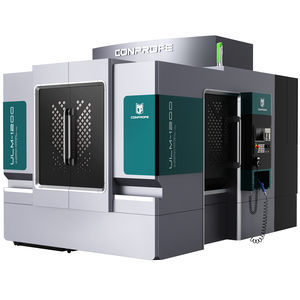

Ultrasonic CNC machining center ULM-400C3-axisverticalgantry type

Add to favorites

Compare this product

Characteristics

- Number of axes

- 3-axis

- Spindle orientation

- vertical

- Structure

- gantry type, table type

- Machined material

- for cast iron, for aluminum, for steel, for copper, for non-ferrous metals, for stainless steel, for brass, for composites, for glass, for hard and brittle materials, for ceramics, for quartz

- Spindle mount

- HSK-E32

- Number of tool stations

- 11 tools

- Associated functions

- milling, engraving, drilling

- Applications

- for the aeronautical industry, for the automobile industry, for medical applications, for titanium, for aeronautics, for small parts production, optical, for cast iron, for the steel industry, for small workpieces, dental

- Other characteristics

- high-speed, high-speed, high-performance, high-productivity, compact, high-rigidity, high-precision, CE, ultrasonic

- X travel

400 mm

(15.75 in)- Y travel

400 mm

(15.75 in)- Z travel

150 mm

(5.91 in)- Rotational speed

Max.: 40,000 rpm

(251,327 rad.min-1)Min.: 0 rpm

(0 rad.min-1)- Power

10 kVA

(13.6 hp)- Work feed X-axis

10 m/min

- Work feed Y-axis

10 m/min

- Work feed Z-axis

10 m/min

- Table load capacity

100 kg

(220 lb)- Tool weight (max)

3 kg

(6.6 lb)- Positioning accuracy

0.005 mm

(0.0002 in)- Repeatability

0.003 mm

(0.00012 in)- Weight

2,100 kg

(4,629.71 lb)- Overall length

1,245 mm

(49 in)- Overall width

1,750 mm

(68.9 in)- Overall height

2,130 mm

(83.9 in)

Description

With excellent product design, ULM-400C generates great ROI with its stable performance in high-speed and high-precision processing for various industries. The integration of Conprofe’s ultrasonic machining technology expands the range of processable materials from the commonly used aluminum alloy, stainless steel, etc. to hard-brittle materials like glass, ceramics and HTP composite materials.

✅Advanced Ultrasonic Machining Technology

Ultrasonic machining adds 16k~60kHz vibration to the rotating cutting tool, which effectively reduces cutting forces by over 30%. Rotary ultrasonic machining results in higher material removal rate, improved hole accuracy with superior surface finish and longer tool life vs. traditional machining.

Example: D0.5*5mm Hole Drilling of Glass Showerhead

· 72% cycle time reduction

· 68% edge chipping reduction

· Tool life exceeding 1,200 holes

✅Compact Design with High Rigidity

- The machine excels in rigidity and stability with its gantry structure, one-piece design of crossbeam and column along as well as CAE optimization.

- Taking up only 2.5m2 floor space and weighing merely 2.1 tons, ULM-400C enables more flexible and cost-effective workshop layout planning.

✅High Speed and High Accuracy

With spindle speed up to 40,000rpm, ULM-400C is a perfect solution for workpieces demanding high precision and surface integrity, especially for mirror finish.

✅More Upgrade Options Available

to meet different machining demands and combining more processing operations into one machine:

- T22 tool magazine

- 4th/5th axis rotary table

Contact us for free test cut NOW: sales-international@conprofetech.com!

VIDEO

Catalogs

ULM-400C

2 Pages

Exhibitions

Meet this supplier at the following exhibition(s):

Related Searches

- Conprofe machining center

- Conprofe vertical machining center

- Conprofe 3-axis machining center

- Conprofe precision machining center

- CNC milling machine

- Conprofe 5-axis machining center

- Vertical CNC milling machine

- Conprofe high-precision machining center

- 3-axis CNC milling machine

- Conprofe rigid machining center

- Conprofe high-performance machining center

- Conprofe gantry machining center

- Conprofe high-rigidity machining center

- Conprofe milling machining center

- Conprofe high-productivity machining center

- Conprofe column type machining center

- Conprofe cutting machining center

- Conprofe aluminum machining center

- Conprofe machining center with pallet changer

- Precision CNC milling machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.