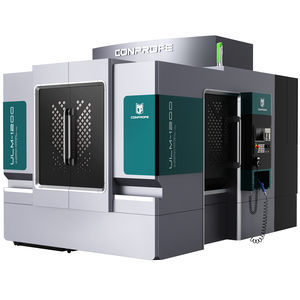

Ultrasonic CNC machining center ULM-600B3-axisverticalfor composites

Add to favorites

Compare this product

Characteristics

- Number of axes

- 3-axis

- Spindle orientation

- vertical

- Machined material

- for composites, for hard and brittle materials

- Spindle mount

- HSK-E40

- Number of tool stations

- 13 tools

- Associated functions

- milling, engraving, drilling

- Other characteristics

- precision, ultrasonic, all-in-one

- X travel

600 mm

(23.62 in)- Y travel

500 mm

(19.69 in)- Z travel

300 mm

(11.81 in)- Rotational speed

Min.: 0 rpm

(0 rad.min-1)Max.: 30,000 rpm

(188,496 rad.min-1)- Power

14 kVA

(19.03 hp)- Work feed X-axis

10 m/min

- Work feed Y-axis

10 m/min

- Work feed Z-axis

10 m/min

- Table load capacity

300 kg

(661 lb)- Tool weight (max)

3 kg

(6.6 lb)- Positioning accuracy

0.005 mm

(0.0002 in)- Repeatability

0.003 mm

(0.00012 in)- Weight

5,000 kg

(11,023.11 lb)- Overall length

1,850 mm

(72.8 in)- Overall width

2,100 mm

(82.7 in)- Overall height

2,395 mm

(94.3 in)

Description

- All-in-one machine tool for processing hard-brittle materials, composite materials, high gloss/mirror finish, small parts, micro-holes, etc.

- HSK-E40 ultrasonic spindle with a max. speed of 30,000rpm available

- Supercritical Carbon Dioxide (ScCO2) Cryogenic Cooling System and MQL internal cooling system available for clean machining

- Extended Tool Magazine available to meet various machining needs

- 5-axis Rotary tables addable to realize 5-axis positioning and 5-axis simultaneous machining of geometrically complex parts

- HNC 918D system (standard) and SIEMENS 828D system (optional) available

Application

Ideally suited for ultrasonic machining of hard-brittle materials (ceramics, sapphire, glass, silicon carbide) and other hard-to-cut materials, and high-precision and high-efficiency machining of metal materials (aluminium alloy, stainless steel, etc.)

Suitable for machining precision parts made of hard-brittle materials (e.g. ceramic, sapphire, glass, silicon carbite etc.), carbon-fiber composites, superalloy (e.g. titanium alloy) and other hard-to-cut materials

Features

Conprofe independently-developed Ultrasonic Machining System to solve issues in machining hard-to-cut materials

Optional Supercritical CO₂ or MQL Cooling System to realize clean machining

Two options for screw guides to meet requirements on machining hard-brittle materials and metal

Front-door loading & unloading and side-door operation available with facilitative operating position

High-precision machining with up to 3μm of positioning accuracy and 2μm of repeatability

Single/double/T40 chain-type tool magazine available

With chip auger for smooth and thorough chip removal

VIDEO

Catalogs

ULM-600B

2 Pages

Exhibitions

Meet this supplier at the following exhibition(s):

Related Searches

- Conprofe machining center

- Conprofe vertical machining center

- Conprofe 3-axis machining center

- Conprofe precision machining center

- CNC milling machine

- Conprofe 5-axis machining center

- Vertical CNC milling machine

- Conprofe high-precision machining center

- 3-axis CNC milling machine

- Conprofe rigid machining center

- Conprofe high-performance machining center

- Conprofe gantry machining center

- Conprofe high-rigidity machining center

- Conprofe milling machining center

- Conprofe high-productivity machining center

- Conprofe column type machining center

- Conprofe cutting machining center

- Conprofe aluminum machining center

- Conprofe machining center with pallet changer

- Precision CNC milling machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.